Rotary Evaporators: Efficient Solutions for Solvent Removal

Understanding the Role of Rotary Evaporators in Laboratory Settings

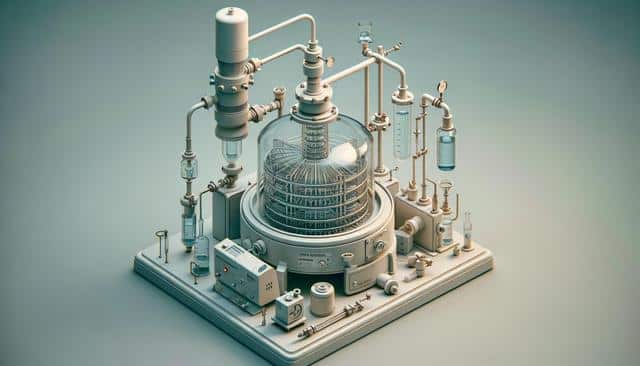

Rotary evaporators, often referred to as rotovaps, play a critical role in modern laboratory workflows where the removal of solvents from samples is required. These devices operate by reducing the pressure within a sealed system, allowing solvents to evaporate at lower temperatures. This method is particularly effective for handling temperature-sensitive compounds and is widely used in chemistry, biology, and pharmaceutical research. Through a rotating flask and controlled heating, a rotary evaporator maximizes surface area exposure and promotes efficient evaporation, making it a staple for labs that perform frequent concentration or purification tasks.

The basic components of a rotary evaporator include a motor unit, a vapor duct, a vacuum system, a heated water or oil bath, a condenser, and a collection flask. Each component plays a crucial role in ensuring the system functions optimally. For instance, the motor rotates the evaporation flask to increase surface area, while the vacuum system lowers the pressure, allowing the solvent to evaporate more easily and at lower temperatures. This prevents degradation of sensitive compounds, making rotary evaporators ideal for delicate laboratory processes.

Key Applications and Benefits

Rotary evaporators are highly versatile and serve a wide range of applications in research and industrial laboratories. Their ability to gently and efficiently remove solvents makes them essential in several core processes, including:

- Sample concentration for analysis

- Solvent recycling and recovery

- Purification of reaction products

- Distillation of temperature-sensitive compounds

One of the most notable advantages of using a rotary evaporator is the preservation of compound integrity. Traditional evaporation methods using heat alone can degrade sensitive molecules, while rotary evaporation ensures minimal thermal stress. Additionally, the system’s efficiency helps laboratories save time and reduce solvent waste, contributing to more sustainable and cost-effective operations.

Components and How They Work Together

Understanding how the individual parts of a rotary evaporator work together can provide insight into its overall efficiency. The rotating flask, which contains the sample, is partially submerged in a heated bath. As it rotates, the surface area of the liquid exposed to evaporation increases. Simultaneously, a vacuum pump reduces the system’s pressure, allowing the solvent to boil at a lower temperature. The vapor then travels through a condenser where it cools and becomes liquid again, finally collecting in a separate flask for reuse or disposal.

This coordinated mechanism allows for a continuous, gentle evaporation process that is significantly faster and safer than traditional methods. The user can control critical parameters such as bath temperature, rotation speed, and vacuum level, allowing for customization based on the specific solvent and sample requirements. These features make rotary evaporators a valuable tool for achieving consistent and reliable results in various lab procedures.

Considerations for Choosing a Rotary Evaporator

When selecting a rotary evaporator for laboratory use, several factors should be considered to ensure it meets specific operational needs. These include:

- Volume capacity: Ensure the system can handle the sample sizes typically used in your lab.

- Vacuum control: Precision in pressure control allows for better solvent removal and sample protection.

- Temperature range: The ability to control and maintain specific temperatures is crucial for sensitive compounds.

- Ease of use and safety features: Features such as digital displays, automatic lift systems, and safety shutoffs enhance usability and reduce risk.

Additionally, the build quality and durability of the system should not be overlooked. Investing in a well-regarded rotary evaporator can lead to long-term efficiency gains and reduced maintenance costs. While no single model suits every lab, identifying priority features based on your workflow will help in making an informed buying decision.

Maintenance and Best Practices

To ensure consistent performance and longevity, proper maintenance and operation of rotary evaporators is essential. Regular cleaning of components such as the condenser, vacuum seals, and flasks helps prevent contamination and buildup that could affect performance. It’s also important to check and replace worn gaskets and seals to maintain vacuum integrity.

Best practices include:

- Using compatible solvents to avoid damage to internal components

- Gradually adjusting vacuum and temperature settings to prevent sudden pressure changes

- Monitoring solvent levels to avoid overfilling the flask

- Storing the unit properly when not in use, particularly the glass components, to avoid breakage

Following these guidelines can help labs maintain the efficiency and reliability of their rotary evaporators. Training staff on correct usage and safety protocols also contributes to a smoother and safer laboratory environment.

Conclusion: Enhancing Lab Efficiency with Rotary Evaporators

For laboratories engaged in processes that require solvent removal, concentration, or purification, rotary evaporators offer a reliable and efficient solution. Their ability to perform solvent removal at lower temperatures protects sample integrity and speeds up workflows, making them a valuable addition to a wide range of scientific disciplines. By understanding their operation, choosing the right model, and implementing good maintenance practices, labs can maximize the benefits of this essential equipment. Whether used in research, quality control, or production, rotary evaporators support streamlined and precise laboratory operations.