Top Finned Double Pipe Heat Exchangers for Efficient Thermal Transfer

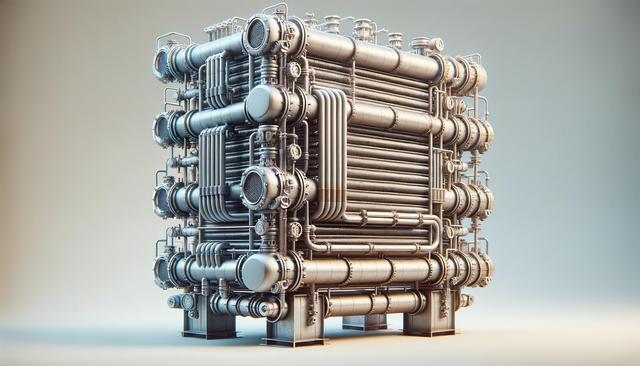

Understanding Finned Double Pipe Heat Exchangers

Finned double pipe heat exchangers are widely used in various industrial applications where temperature regulation is critical. These systems consist of two concentric pipes—one inside the other—where heat transfer takes place between fluids flowing in opposite directions. The addition of fins on the inner or outer pipe enhances the surface area, improving the rate of thermal exchange. This design is particularly effective in handling high-pressure fluids and offers robust performance even in demanding environments. By increasing the surface area, finned configurations promote better efficiency without significantly enlarging the unit’s footprint, making them ideal for compact installations.

Industries such as chemical processing, oil and gas, and HVAC systems benefit from the precision and control these exchangers offer. In environments where consistent temperature control is crucial, the improved thermal efficiency of finned models can lead to better energy management and reduced operational costs. Their modular design also allows for scalability, enabling facilities to expand capacity without overhauling existing infrastructure.

Key Advantages of Finned Designs

One of the primary reasons finned double pipe heat exchangers stand out is their ability to deliver high thermal transfer rates without requiring large volumes of fluid. The fins facilitate rapid heat dissipation or absorption, which makes them suitable for both heating and cooling cycles. These units are often chosen for systems where:

- Space constraints demand compact yet efficient solutions

- High thermal gradients are required for quick temperature shifts

- Durability is essential due to corrosive or high-pressure operating conditions

Another notable advantage is their mechanical simplicity. Unlike more complex heat exchanger systems, finned models require minimal maintenance and are easier to clean and inspect. This helps reduce downtime and extends the operational life of the equipment. The use of corrosion-resistant materials such as stainless steel or specialized alloys further enhances their longevity, especially in aggressive industrial settings.

Cost-Effective Performance for Long-Term Use

While upfront costs for finned double pipe heat exchangers may be higher than simpler designs, their long-term cost-effectiveness is evident in reduced energy consumption and lower maintenance requirements. These units are engineered to provide consistent performance over extended periods, which translates to long-term savings. By reducing the need for auxiliary equipment such as pumps or additional cooling mechanisms, they simplify system architecture and improve overall reliability.

Additionally, these exchangers support a wide range of fluid types, including water, oils, and refrigerants, making them highly versatile. This compatibility allows companies to consolidate their thermal systems, reducing the need for multiple exchanger types across different processes. Many manufacturers offer customizable configurations, allowing for tailored solutions that meet specific flow rates, temperature ranges, and space requirements.

Applications Across Industrial Sectors

Finned double pipe heat exchangers are not limited to a single industry. Their adaptability and efficiency make them suitable for diverse applications across multiple sectors. In the chemical industry, they are used for process heating and cooling, ensuring that reactions occur under optimal temperature conditions. In power generation, they help manage turbine and generator temperatures, contributing to consistent energy output.

In food and beverage production, these exchangers help maintain hygienic temperature control during pasteurization or chilling processes. Their easy-to-clean design supports compliance with sanitation standards. Other industries where these systems are commonly deployed include:

- Pharmaceutical manufacturing

- Petrochemical refining

- Metal processing and fabrication

- Renewable energy systems, such as solar thermal setups

Each application benefits from the ability to finely tune heat transfer based on process requirements, ensuring product quality and operational efficiency.

Choosing the Right Finned Double Pipe Heat Exchanger

Selecting the appropriate finned double pipe heat exchanger involves assessing several critical factors. These include the type of fluids involved, desired temperature ranges, required flow rates, and the environmental conditions in which the equipment will operate. Customization options offered by manufacturers allow for precise alignment with these parameters, ensuring optimal performance and energy efficiency.

Other considerations include:

- Material compatibility with process fluids

- Thermal conductivity and pressure drop requirements

- Ease of installation and integration into existing systems

- Maintenance access and serviceability

Consulting with an experienced heat exchanger supplier can greatly assist in identifying the most appropriate model. It’s also beneficial to evaluate lifecycle costs, including energy consumption and maintenance frequency, to understand the true value over time. Investing in a high-quality, well-matched system can lead to substantial efficiency gains and a more sustainable operation.

Conclusion: Efficient Solutions for Industrial Thermal Management

Finned double pipe heat exchangers offer a reliable and efficient approach to industrial thermal management. Their enhanced surface area and durable construction make them a smart choice for operations requiring consistent heating or cooling. By balancing performance with cost-effectiveness, these systems support long-term reliability and energy efficiency across various sectors. Whether managing high-pressure fluids or operating in compact spaces, their versatility and efficiency make them a valuable component in modern industrial setups. Careful selection and proper maintenance ensure these exchangers continue to deliver value throughout their operational lifespan.