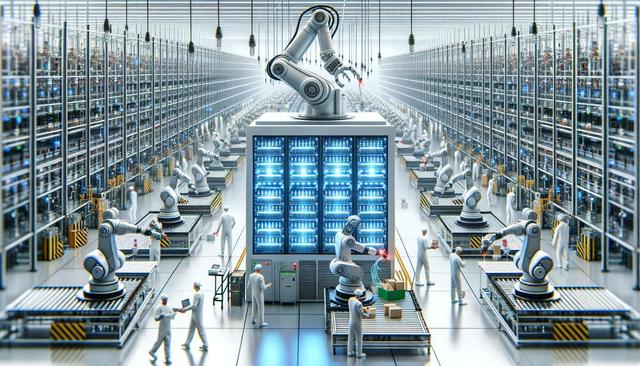

Understanding Industrial Computing in Modern Manufacturing

Industrial computing refers to the use of specialized computer systems designed for the harsh environments and demanding needs of manufacturing and production facilities. These systems are built to withstand extreme temperatures, dust, moisture, and vibration, making them ideal for continuous operation in industrial settings. Unlike general-purpose computers, industrial computers are engineered for reliability and integration with control systems, sensors, and machinery.

These robust computing platforms are essential for collecting, processing, and analyzing data in real-time. They serve as the foundation for automation processes, enabling efficient monitoring and control across production lines. Whether embedded within machinery or functioning as centralized control units, industrial computers help drive performance by providing actionable insights from production data. Their integration with software platforms and industrial protocols ensures seamless communication among various components of the automation ecosystem.

Automation Technologies Driving Smarter Operations

Automation in industrial environments involves the use of control systems, robotics, and information technologies to handle different processes with minimal human intervention. These technologies contribute significantly to improving productivity, quality, and safety in manufacturing operations. Smart automation systems utilize real-time data to make decisions, adjust parameters, and optimize performance dynamically.

Key automation technologies include:

- Programmable Logic Controllers (PLCs): Essential for executing real-time control tasks with high reliability.

- Supervisory Control and Data Acquisition (SCADA) systems: Used for monitoring and controlling plant processes remotely.

- Industrial Internet of Things (IIoT): Devices and sensors that gather and transmit data to enhance situational awareness and predictive maintenance.

- Machine learning algorithms: Enable systems to adapt and improve performance based on historical data and trend analysis.

These technologies allow manufacturers to identify inefficiencies, reduce downtime, and lower operational costs while maintaining high consistency in output quality. Automation also enhances worker safety by reducing exposure to hazardous tasks.

Benefits of Integrating Industrial Computing with Automation

The combination of industrial computing and automation offers a wide range of operational advantages. By integrating intelligent systems into the production workflow, companies can achieve higher levels of precision, scalability, and responsiveness. Some of the key benefits include:

- Enhanced process visibility: Real-time monitoring provides insights into every stage of production.

- Improved decision-making: Data-driven analytics support proactive management and operational adjustments.

- Reduced human error: Automated systems perform repetitive tasks with consistent accuracy.

- Energy efficiency: Smart controls optimize energy consumption based on demand and usage patterns.

These improvements contribute to more sustainable and agile manufacturing models. As factories become more connected, the ability to collect and act on operational data in real-time becomes a competitive advantage.

Challenges and Considerations in Implementation

While the benefits of industrial computing and automation are substantial, implementing these technologies requires careful planning and consideration. One of the primary challenges is system integration—ensuring that new technologies work seamlessly with legacy systems and equipment. Additionally, cybersecurity becomes a growing concern as more devices connect to industrial networks.

Other key considerations include:

- Initial investment costs: Upfront expenses for hardware, software, and training can be significant.

- Workforce adaptation: Employees need to be trained to operate and maintain new systems.

- Maintenance requirements: Industrial computers and automation equipment must be regularly maintained to ensure reliability.

- Scalability: Solutions should be flexible to accommodate future growth and technological advancements.

Addressing these challenges requires a strategic approach, including stakeholder engagement, cross-functional collaboration, and a clear roadmap for digital transformation.

Future Trends in Industrial Computing and Automation

The future of industrial computing and automation is shaped by innovations that enhance connectivity, intelligence, and interoperability. Edge computing, for instance, is gaining traction for its ability to process data closer to the source, reducing latency and bandwidth needs. This is particularly useful in time-sensitive applications such as quality control and machine diagnostics.

Advancements in artificial intelligence and machine learning are also transforming automation capabilities. Predictive analytics can detect anomalies before they cause downtime, while adaptive systems can self-tune operations in response to changing conditions. Additionally, the growing adoption of open standards and modular architectures is making it easier to customize and scale automation solutions.

As technology continues to evolve, we can expect a shift toward more autonomous operations, where systems not only execute tasks but also learn and optimize themselves over time. This trend aligns with the broader goals of Industry 4.0 and smart manufacturing, where interconnected systems work together to create more efficient, flexible, and resilient production environments.

Conclusion: Building Smarter Operations Through Technology

For manufacturers and industrial operators, integrating industrial computing and automation is a strategic move toward smarter, more efficient operations. These technologies enable better control, visibility, and adaptability across production processes, paving the way for improved productivity and reduced operational costs. By embracing this digital transformation, companies position themselves to respond more effectively to market demands, technological advancements, and sustainability goals. With the right planning and execution, industrial computing and automation can serve as the cornerstone of a more intelligent and agile manufacturing future.

Leave a Reply