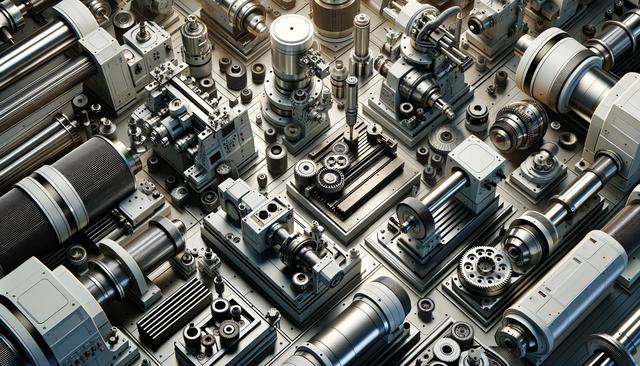

Understanding the Role of Metal Cutting Machines in Industry

In modern manufacturing and fabrication, metal cutting machines are essential tools for shaping, resizing, and refining metal components. These machines are employed across various industries including construction, automotive, aerospace, and shipbuilding. They offer a combination of speed, precision, and versatility that manual methods cannot match. Whether producing large structural components or intricate custom parts, these machines contribute significantly to operational efficiency and product quality. The choice of a machine depends on several factors, such as material type, desired finish, cut complexity, and production volume.

Metal cutting machines are generally classified into categories based on their cutting method. Common types include mechanical saws, laser cutters, plasma cutters, waterjet machines, and electrical discharge machines (EDMs). Each of these has its own strengths and ideal use cases. For example, mechanical saws are effective for straight cuts in thicker materials, while laser cutters are preferred for fine, precise cuts with minimal material waste. Understanding these differences is critical when selecting equipment for specific projects or applications.

Laser Cutting Machines: Precision and Speed

Laser cutting machines have become a popular choice in industries that require accurate and repeatable cuts. They operate by directing a high-powered laser beam onto the metal surface, melting or vaporizing the material along the desired path. These machines are especially effective on materials like stainless steel, aluminum, and mild steel. With computer numerical control (CNC) systems, laser cutters offer high levels of automation and accuracy, making them suitable for mass production and custom fabrication alike.

Benefits of laser cutting machines include:

- Exceptional cutting precision with tight tolerances

- Minimal material deformation due to low heat-affected zones

- Clean edges that reduce the need for secondary processes

- High-speed operation for increased throughput

Despite their advantages, laser cutters are best suited for thinner materials, and the initial investment can be significant. However, their operational efficiency often offsets these costs over time, particularly for high-volume production environments.

Plasma Cutters: Power for Thick Materials

Plasma cutting machines are widely used for cutting through thicker metals quickly and effectively. They utilize an electrically conductive gas to transfer energy from a power supply to the cutting torch, creating a high-temperature plasma arc that melts the metal. These cutters are commonly used in heavy industries such as shipbuilding, structural steel fabrication, and industrial maintenance.

Key advantages of plasma cutters include:

- High cutting speed on thick and conductive metals

- Ability to pierce through materials without pre-drilling

- Lower operating costs compared to some other cutting technologies

- Portability and ease of use in various environments

While plasma cutters are not as precise as laser cutters, especially on thinner materials, their speed and power make them an excellent choice for demanding cutting tasks. They are ideal for use in environments where robustness and efficiency are more critical than ultra-fine detail.

Mechanical Saws and Their Versatility

Mechanical saws, such as band saws and circular saws, remain a dependable choice for many fabrication shops. These machines cut using a toothed blade and are known for their simplicity, reliability, and cost-effectiveness. Mechanical saws are especially useful in cutting solid metal stock, tubing, and structural beams. They are suitable for both straight and angled cuts and can handle a variety of metal types and thicknesses.

Advantages of mechanical saws include:

- Low maintenance and operational costs

- Ability to cut large and heavy metal sections

- Ease of operation and quick setup

- Compatibility with both ferrous and non-ferrous metals

However, mechanical saws may not offer the same level of precision or edge quality as laser or waterjet cutters. They are often used as a first-step cutting solution, followed by more refined processing when needed. Their role in workshop environments remains vital due to their robust performance and broad applicability.

Selecting the Right Machine for Your Application

Choosing the appropriate metal cutting machine depends heavily on the specific requirements of your manufacturing or fabrication project. Factors to consider include material type, thickness, required precision, production volume, and budget constraints. In many cases, facilities may benefit from having multiple types of cutting machines to handle a variety of tasks efficiently.

When evaluating equipment, it’s also important to consider:

- The level of automation and integration with existing systems

- Operator training and safety features

- Maintenance requirements and service availability

- Energy consumption and operational efficiency

Investing in the right cutting technology can lead to significant improvements in productivity, quality, and cost savings over time. By aligning machine capabilities with operational needs, businesses can enhance their competitive edge in the market.

Conclusion: Enhancing Fabrication with the Right Cutting Tools

Metal cutting machines play a central role in shaping the future of industrial fabrication. From high-precision laser cutters to powerful plasma systems and dependable mechanical saws, each machine offers specific benefits tailored to different applications. Understanding these tools and selecting the right equipment for your needs can help streamline operations, improve output quality, and maintain cost-effectiveness. For manufacturers and fabricators seeking to optimize their processes, investing in the appropriate metal cutting technology is a practical and strategic decision.

Leave a Reply