Understanding the Role of Thermal Oxidizers in Industrial Emission Control

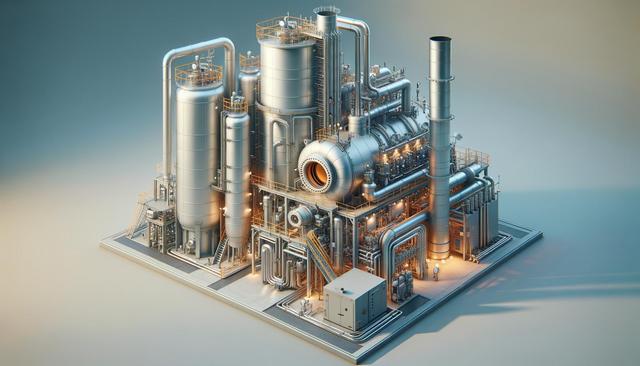

Thermal oxidizers are a widely used technology in industrial settings for controlling air pollution and ensuring environmental compliance. These systems are engineered to treat exhaust air streams that contain volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and other hydrocarbon-based emissions. By exposing these pollutants to high-temperature combustion, thermal oxidizers convert harmful substances into less harmful byproducts such as carbon dioxide and water vapor. One of the key players in this field, Zeeco thermal oxidizers, are known for their efficiency and adaptability in various industrial applications.

Industries such as chemical manufacturing, petroleum refining, pharmaceuticals, and food processing often rely on thermal oxidizers as part of their air pollution control strategy. The way these systems function makes them suitable for handling a wide range of emission profiles, from low to high concentration waste gas streams. Their design flexibility allows them to be integrated easily into existing process lines, making them a practical solution for facilities aiming to minimize their environmental impact.

How Zeeco Thermal Oxidizers Work

Zeeco thermal oxidizers operate on a straightforward but highly effective principle: combustion. The process begins when the contaminated air stream is directed into the oxidizer’s combustion chamber. Within this chamber, a burner heats the air to temperatures typically ranging between 1,400°F to 1,800°F (760°C to 980°C). This high temperature ensures that organic pollutants are broken down into basic, non-toxic components.

The key stages of operation include:

- Pre-treatment of the waste gas stream (if necessary)

- Introduction of the gas into the combustion chamber

- High-temperature oxidation of pollutants

- Emission of treated gases through a stack

Zeeco systems are often tailored with features to enhance thermal efficiency, such as heat recovery units and advanced control systems. These enhancements reduce fuel consumption and operational costs, contributing to more sustainable industrial practices.

Applications Across Various Industries

Thermal oxidizers have a broad application scope, and Zeeco designs are found across many sectors. In industries where cleanliness and air quality are paramount, such as food production or pharmaceuticals, emission control is not just a regulatory requirement but also a matter of product integrity and workplace health. Zeeco thermal oxidizers help meet stringent air quality standards while maintaining production efficiency.

Common industries that benefit from thermal oxidizers include:

- Petrochemical plants

- Paint and coating manufacturing

- Printing facilities

- Waste management and recycling

- Semiconductor manufacturing

Each of these sectors produces unique emission profiles, and Zeeco’s flexible design options allow for customization to specific operational needs. From regenerative thermal oxidizers (RTOs) to direct-fired models, the technology can be adapted to suit varying flow rates, contaminant concentrations, and thermal requirements.

Efficiency and Environmental Impact

One of the major drivers for adopting thermal oxidizers is their ability to significantly reduce the environmental footprint of industrial operations. Zeeco thermal oxidizers are engineered to achieve high destruction removal efficiency (DRE), often exceeding 99%. This ensures that very little of the original pollutants are released into the atmosphere.

Efficiency in these systems is often enhanced through:

- Heat recovery systems that preheat incoming waste gases

- Smart control systems for optimized burner operation

- Modular components for ease of maintenance and scalability

By effectively converting toxic compounds into harmless byproducts, thermal oxidizers contribute to cleaner air and a healthier environment. Their use is an important step toward achieving environmental compliance, reducing greenhouse gas emissions, and supporting sustainable industrial growth.

Maintenance and Operational Considerations

Maintaining a thermal oxidizer is critical to ensuring consistent performance and long-term reliability. Zeeco thermal oxidizers are often designed with user-friendly interfaces and robust components to minimize downtime. However, like all combustion-based systems, they require regular inspection and maintenance to perform at peak levels.

Typical maintenance tasks include:

- Burner inspection and cleaning

- Monitoring of temperature and pressure sensors

- Checking insulation and refractory linings

- Ensuring proper airflow and gas flow rates

Proper training for operational staff and scheduled maintenance programs can help extend the life of the equipment and avoid costly disruptions. Zeeco also provides technical support and field services to assist with system optimization and troubleshooting. With the right operational practices, these systems can remain effective and compliant for many years.

Conclusion: Supporting Cleaner Industry Through Reliable Emission Control

As industries face growing pressure to reduce emissions and operate more sustainably, thermal oxidizers play a vital role in meeting these expectations. Zeeco thermal oxidizers offer a reliable and efficient solution for controlling harmful air pollutants through the use of high-temperature combustion. Their adaptability, high destruction efficiency, and design flexibility make them a suitable choice for a wide range of industrial applications. By investing in well-designed emission control technology, companies can not only meet regulatory standards but also contribute to a cleaner and safer environment for future generations.

Leave a Reply