Understanding the Role of Plug Flow Reactors in Chemical Processing

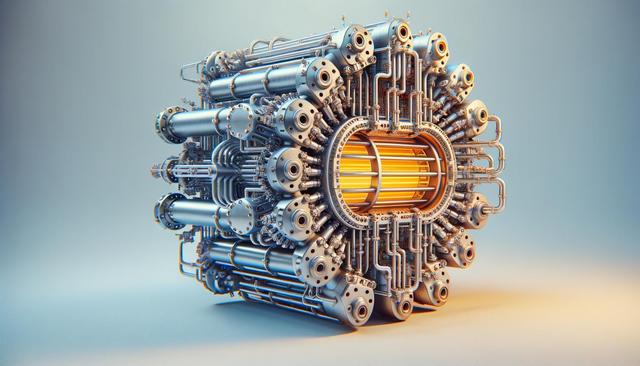

Plug flow reactors (PFRs) are widely used in the chemical industry due to their ability to handle continuous reactions with high efficiency. In a PFR, reactants flow through a cylindrical pipe in one direction without back-mixing, ensuring that chemical reactions occur progressively along the flow path. This flow behavior allows for precise control over reaction time and temperature, both of which are critical for optimizing product yields and maintaining safety standards. Heat exchangers integrated within or alongside PFR systems contribute significantly to maintaining these controlled conditions by managing the energy balance during the reaction process.

Typically, the integration of a heat exchanger with a plug flow reactor allows operators to either remove excess heat generated by exothermic reactions or supply heat to maintain the temperature for endothermic processes. This thermal management is essential for preventing hot spots, minimizing side reactions, and ensuring consistent product quality. The combination of plug flow dynamics and targeted thermal exchange makes this setup especially suitable for processes involving temperature-sensitive materials or reactions with narrow operating windows.

Design Considerations for Plug Flow Reactor Heat Exchangers

Designing a plug flow reactor heat exchanger involves careful consideration of several factors to ensure optimal performance. The geometry of the reactor, type of reaction, flow rate, and desired temperature profile all influence the selection and configuration of the heat exchanger. Common types of heat exchangers used in conjunction with PFRs include:

- Shell-and-tube heat exchangers: Ideal for high-pressure applications and large-scale operations.

- Double pipe heat exchangers: Suitable for smaller scales and simpler setups.

- Plate heat exchangers: Offer high heat transfer efficiency with compact design.

The choice among these depends on the thermal load, available space, and maintenance preferences. Additionally, materials of construction must be compatible with the chemical properties of the reactants and products to prevent corrosion or degradation over time.

Operational Efficiency and Thermal Control

One of the main advantages of using a plug flow reactor heat exchanger is the ability to maintain a consistent temperature profile along the reactor length. This is essential for achieving uniform reaction rates and avoiding thermal runaway scenarios. By strategically placing heat exchange zones along the reactor, operators can fine-tune the thermal input or output at different stages of the reaction process. This level of control can significantly improve process efficiency and energy savings. Key benefits include:

- Enhanced reaction selectivity and conversion rates

- Reduced energy consumption through targeted heating or cooling

- Improved safety due to better temperature regulation

In continuous production environments, such precise thermal management also supports scalability and reproducibility, making plug flow systems with integrated heat exchangers a reliable choice for modern chemical manufacturing.

Applications Across Industries

Plug flow reactor heat exchangers are used in a wide range of industries, each with unique requirements for chemical processing and thermal control. In the pharmaceutical sector, for example, these systems are used to synthesize active ingredients where strict temperature control is necessary to maintain product integrity. In the petrochemical industry, they facilitate catalytic reactions that require sustained high temperatures under controlled conditions. Other notable sectors include:

- Food and beverage: For pasteurization and continuous cooking processes

- Fine chemicals: Where precise reaction conditions determine product quality

- Waste treatment: To support thermal reactions in pollution control processes

The flexibility and efficiency of plug flow reactor heat exchangers make them adaptable to a variety of chemical engineering challenges. Their ability to integrate with process automation systems further enhances their appeal for industries focused on operational excellence and regulatory compliance.

Maintenance and Performance Optimization

To maintain the performance of a plug flow reactor heat exchanger system, regular inspection and maintenance are critical. Over time, scaling, fouling, or corrosion can reduce heat transfer efficiency and compromise reaction conditions. Preventive maintenance strategies include:

- Routine cleaning of heat exchange surfaces

- Monitoring for leaks, pressure drops, or temperature inconsistencies

- Using corrosion-resistant materials and protective coatings

Additionally, performance can be optimized by employing advanced control systems that monitor temperature, flow rate, and reaction progress in real-time. These systems can automatically adjust thermal inputs to match process demands, reducing downtime and maximizing throughput. Investing in analytics and data-driven insights can also help operators identify trends and anticipate maintenance needs, further enhancing the reliability of the system.

Conclusion

Plug flow reactor heat exchangers play a vital role in modern chemical processing by offering precise thermal control and efficient energy management. Their application spans across multiple industries where consistent product quality and process efficiency are priorities. By understanding the design principles, operational strategies, and maintenance requirements, engineers and plant operators can fully leverage the advantages of these systems. Whether in pharmaceuticals, petrochemicals, or environmental applications, plug flow reactor heat exchangers provide a dependable solution for meeting complex thermal and chemical processing needs.

Leave a Reply