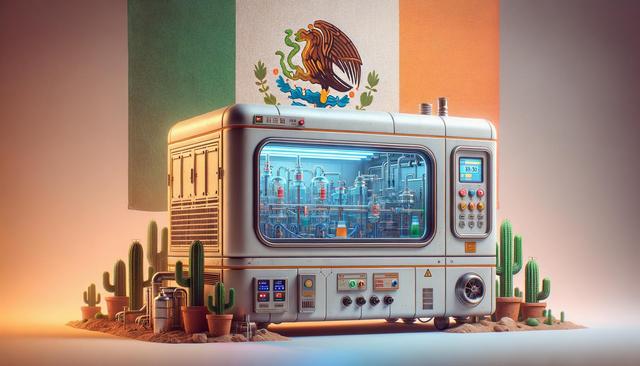

Understanding UV Sterilization Technology

Ultraviolet (UV) sterilization is a disinfection method that uses short-wavelength ultraviolet light to inactivate or destroy microorganisms. This technology is widely recognized for its ability to eliminate bacteria, viruses, and fungi without the use of chemicals. In industrial settings, UV sterilizers are applied to air, water, and surfaces, offering a reliable solution for maintaining strict hygiene standards. UV-C light, in particular, is effective in disrupting the DNA and RNA of pathogens, rendering them harmless and unable to reproduce. This makes UV sterilization a preferred choice for industries in Mexico that must adhere to health regulations and environmental safety standards.

Industries such as food processing, pharmaceuticals, and manufacturing are increasingly integrating UV sterilization systems into their operations. These systems are engineered to deliver consistent performance in high-demand environments, reducing the risk of contamination and contributing to safer working conditions. Since the method leaves no chemical residue, it aligns with sustainability efforts and minimizes the need for hazardous waste disposal.

Applications of UV Sterilizers in Mexican Industries

In Mexico, a range of industries benefit from the implementation of industrial-grade UV sterilizers. These systems are tailored to meet the specific needs of sectors where hygiene is paramount. One of the most common applications is water treatment. UV sterilizers are used to disinfect drinking water, wastewater, and water used in production processes, ensuring that microbial content remains within acceptable limits.

Key applications include:

- Air sterilization in HVAC systems to reduce airborne pathogens in factories and office spaces.

- Surface disinfection in food production lines, packaging areas, and laboratories.

- Water purification in beverage manufacturing, health facilities, and agriculture.

By integrating UV sterilizers, companies can meet local and international standards for hygiene and safety. This not only protects consumer health but also enhances the reputation and trustworthiness of Mexican brands in global markets.

Benefits of Industrial-Grade UV Sterilizers

UV sterilizers offer a range of benefits that make them an attractive solution for industrial disinfection. One of the main advantages is their ability to provide effective microbial control without the use of harmful chemicals. This is particularly important for industries that handle sensitive products or operate in environments where chemical disinfection is not feasible.

Additional benefits include:

- Fast disinfection cycles that reduce downtime in production facilities.

- Low maintenance requirements compared to traditional chemical systems.

- Cost efficiency over time, thanks to energy-saving designs and long-lasting UV lamps.

- Minimal environmental impact, as the process does not generate toxic byproducts.

These advantages support industries in achieving operational efficiency while maintaining high standards of cleanliness. As regulations become more stringent, UV sterilization provides a proactive solution that helps businesses stay ahead of compliance requirements in Mexico.

Challenges and Considerations for Implementation

While UV sterilizers present many advantages, there are also challenges to consider when implementing this technology in industrial settings. One key factor is ensuring that the UV system is properly sized and configured for the specific application. Inadequate exposure time or insufficient UV intensity can reduce the effectiveness of disinfection.

Other considerations include:

- Initial investment costs for equipment and installation.

- Regular monitoring to verify performance and lamp efficacy.

- Training for staff to operate and maintain the system safely.

- Compatibility with existing infrastructure and production lines.

Addressing these factors requires a comprehensive approach that includes site assessments, expert consultation, and ongoing maintenance plans. When properly managed, UV sterilization systems can deliver long-term value and reliable performance in demanding industrial environments.

Future Outlook of UV Disinfection in Mexico

As Mexico continues to develop its industrial sector, the demand for advanced sanitation solutions is expected to grow. UV sterilization is well-positioned to play a critical role in this evolution, particularly as businesses seek to comply with international health and quality standards. Technological advancements are also driving improvements in the efficiency and versatility of UV systems, making them more accessible to a wider range of industries.

Future trends likely to influence the adoption of UV sterilizers in Mexico include:

- Automation and integration with smart factory systems.

- Customized solutions for diverse industrial applications.

- Greater emphasis on environmentally responsible disinfection methods.

- Expansion into new sectors such as hospitality, transportation, and public infrastructure.

These developments point to a growing recognition of UV technology as a key component of modern industrial hygiene practices. With continued investment and innovation, UV sterilizers are set to become an essential part of Mexico’s industrial landscape.

Conclusion: Strategic Hygiene for Industrial Success

For industries in Mexico, maintaining high hygiene standards is not just a regulatory requirement—it’s a strategic advantage. UV sterilizers provide a reliable, chemical-free method of disinfection that supports operational efficiency, environmental responsibility, and product safety. From air purification in manufacturing plants to water treatment in beverage production, these systems are proving their value in diverse applications. As technology advances and awareness grows, UV sterilization is poised to become a cornerstone of industrial hygiene across Mexico.

Leave a Reply