Understanding Industrial Reverse Osmosis Systems

Industrial reverse osmosis (RO) systems are advanced water treatment solutions designed to purify large volumes of water efficiently. These systems utilize semipermeable membranes to separate and remove dissolved salts, bacteria, and other contaminants from water, making it suitable for industrial processes, manufacturing, and even human consumption in some cases. The core function of an industrial RO system is based on applying pressure to force water through a membrane that filters out impurities while allowing clean water to pass through. This technology is widely adopted across various sectors due to its consistency, cost-effectiveness over time, and ability to meet strict regulatory requirements for water quality.

Typical applications of industrial RO systems include:

- Pharmaceutical manufacturing

- Food and beverage production

- Power plants

- Textile and dye industries

- Mining and metal processing

Each industry may require different levels of purification, and RO systems can be customized accordingly. This flexibility makes them a valuable investment for operations with varying water quality challenges.

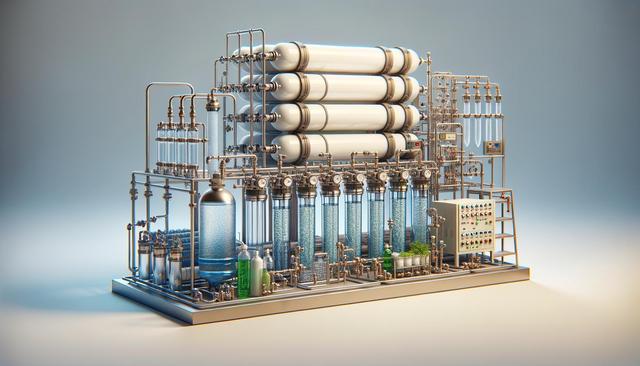

Key Components and How They Work

Industrial RO systems are comprised of several essential components that work together to ensure effective water purification. The primary element is the RO membrane, but other parts play equally important roles in system performance and longevity. These components include:

- Pre-treatment units: Sand filters, carbon filters, or softeners to remove large particulates and chlorine that could damage the membrane.

- High-pressure pump: Provides the necessary pressure to drive water through the RO membrane.

- Membrane modules: The core filtration units that remove dissolved solids and contaminants.

- Post-treatment systems: May include UV sterilizers or re-mineralization units depending on the end-use of the water.

- Control panels and monitoring equipment: Ensure system efficiency and allow real-time adjustments.

The performance of an industrial RO system is heavily dependent on proper design, installation, and maintenance. Regular membrane cleaning and timely replacement of pre-filters are necessary to maintain optimal flow rates and water quality output.

Benefits of Using Industrial RO Systems

There are numerous advantages to incorporating industrial RO systems into water treatment strategies. These systems provide a reliable method for removing a wide range of contaminants, which is particularly important in industries where water quality impacts product integrity or equipment performance. Some key benefits include:

- Consistent water quality that meets regulatory standards

- Reduction in operational costs linked to equipment wear and corrosion

- Minimized environmental impact through efficient use of water resources

- Scalability to match the size and demands of different operations

Additionally, RO systems help reduce the reliance on chemical treatments by using a physical filtration method, which is often safer and more sustainable. Over time, businesses can see financial savings as a result of reduced downtime, improved product outcomes, and less need for chemical handling and storage.

Challenges and Considerations in Implementation

While industrial RO systems offer many advantages, they also come with certain challenges that need to be considered before implementation. One primary consideration is the quality of the feedwater. Water with high levels of hardness, biological contaminants, or suspended solids requires extensive pre-treatment to prevent membrane fouling and degradation. Additionally, these systems can have high upfront costs, particularly for large-scale operations requiring custom configurations and automation.

Important factors to consider during the planning phase include:

- Feedwater composition and variability

- Daily water volume requirements

- Space and infrastructure availability

- Wastewater management and disposal

- Energy consumption and maintenance needs

Working with experienced engineers and water treatment professionals is essential for designing a system that aligns with both operational needs and long-term sustainability goals. Proper training of staff and implementing a proactive maintenance schedule also contribute to maximizing system efficiency and lifespan.

Applications Across Different Industries

The versatility of industrial RO systems makes them suitable for a wide range of industries, each with its own specific water quality requirements. In the pharmaceutical sector, ultra-pure water is needed for formulation and cleaning, while food and beverage industries rely on RO systems to ensure water does not affect taste, safety, or shelf life. In power generation, purified water is essential for boiler feed and cooling systems, where mineral deposits can severely impact performance.

Other applications include:

- Electronics manufacturing: Preventing contamination in delicate components.

- Automotive industry: Ensuring consistency in paint and coating processes.

- Hospital and laboratory settings: Supporting sterilization and cleanroom operations.

In each of these settings, industrial RO systems play a critical role in maintaining operational efficiency, meeting compliance standards, and supporting sustainable water use practices. The adaptability of these systems, combined with their robust performance, makes them a valuable component in modern industrial water management strategies.

Conclusion: Choosing the Right System for Your Needs

Industrial RO systems are a practical and effective solution for high-volume water purification across a wide array of industries. Their ability to deliver consistent, high-quality water makes them a cornerstone of modern industrial operations. However, successful implementation requires careful consideration of system design, feedwater characteristics, and long-term maintenance planning.

For organizations seeking to improve water quality, reduce environmental impact, and meet industry-specific standards, investing in an industrial RO system can offer significant operational advantages. Collaborating with knowledgeable suppliers and service providers ensures that the system is tailored to your specific needs and can adapt as those needs evolve over time.

Leave a Reply