Understanding the Role of Semiconductor Processing Equipment

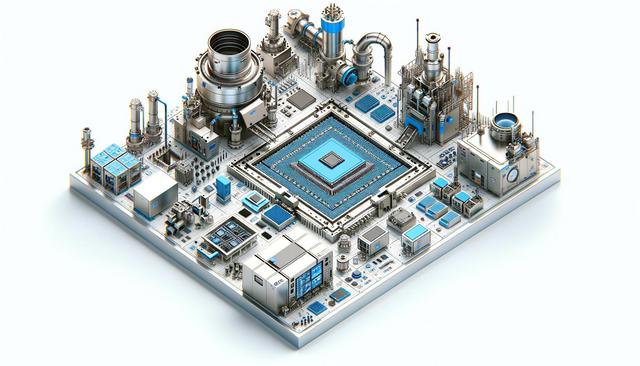

Semiconductor processing equipment forms the backbone of modern chip fabrication, enabling the production of increasingly smaller and more powerful devices. These tools are responsible for executing the intricate steps of etching, deposition, lithography, and cleaning with extreme accuracy. As the demand for high-performance electronics intensifies, so does the need for equipment that can deliver superior reliability and control at the nanoscale level. Each stage of the semiconductor fabrication process is highly sensitive to variations in temperature, pressure, and cleanliness, making precision equipment not just beneficial but essential.

To meet these demands, manufacturers rely on a range of specialized systems, including:

- Photolithography tools for patterning circuits

- Etching systems for removing material with micron-level accuracy

- Deposition equipment to layer materials atom by atom

- Cleaning tools to ensure defect-free surfaces

Each of these components must operate in tandem within a highly controlled environment, often requiring vacuum systems and cleanroom conditions to function optimally. The precise integration of these machines ensures that wafers move through the process seamlessly, with minimal contamination and maximum yield.

Advancements Driving Greater Precision

As semiconductor devices shrink in size and increase in complexity, the demand for more advanced processing equipment continues to grow. Recent innovations have focused on improving alignment accuracy, throughput, and automation. For instance, next-generation lithography systems now incorporate extreme ultraviolet (EUV) technology, allowing for finer patterning at the sub-10 nanometer scale. These advancements are critical for enabling the fabrication of components used in high-speed computing, mobile devices, and artificial intelligence systems.

Enhancements in precision manufacturing have been driven by the following technological developments:

- Advanced metrology and inspection tools that detect sub-nanometer defects

- Closed-loop control systems for better process stability

- Machine learning algorithms to optimize equipment performance in real time

Together, these improvements contribute to higher wafer yields, reduced downtime, and overall cost efficiency. Precision in every phase of manufacturing not only ensures better performance but also supports the longevity and energy efficiency of the final semiconductor products.

The Importance of Cleanroom Integration

Cleanroom environments play a critical role in semiconductor manufacturing, and processing equipment must be designed with contamination control in mind. Even microscopic particles can ruin entire batches of wafers, making cleanliness a top priority. Semiconductor tools are therefore engineered to minimize particle generation and are often housed in modular cleanroom-compatible enclosures.

Key elements of cleanroom-compatible equipment design include:

- Use of low-outgassing materials that do not release contaminants

- Sealed systems that prevent external air or particles from entering

- Integrated filtration systems to maintain air purity

Moreover, equipment must be easy to clean and maintain without compromising the integrity of the controlled environment. Manufacturers often perform regular audits and maintenance protocols to ensure compliance with industry standards for cleanliness and performance. The alignment between equipment design and cleanroom specifications is fundamental to achieving consistent high-quality output in semiconductor production.

Automation and Smart Manufacturing Trends

Modern semiconductor facilities are increasingly adopting automation and smart manufacturing technologies to enhance efficiency and precision. Equipment now features advanced robotics, sensor networks, and software platforms that enable real-time monitoring and adaptive control. These capabilities allow manufacturers to respond swiftly to process variations, equipment wear, and other factors that can impact yield.

Leading trends in smart manufacturing include:

- Predictive maintenance using AI to prevent downtime

- Automated material handling systems for wafer transport

- Digital twins that simulate equipment performance and optimize operations

Automation not only reduces human error but also ensures that each step of the manufacturing process is repeatable and traceable. This level of control is especially valuable in high-volume production environments where even small deviations can result in significant losses. Smart manufacturing, supported by advanced semiconductor processing equipment, is key to maintaining competitiveness in the fast-evolving electronics industry.

Future Challenges and Opportunities

As the semiconductor industry looks ahead, several challenges and opportunities are shaping the evolution of processing equipment. One major challenge is achieving greater precision while reducing energy consumption and environmental impact. Equipment manufacturers are exploring new materials and design architectures to address these concerns. Additionally, the integration of heterogeneous materials and 3D structures in chip design introduces new complexities that demand even more advanced tools and techniques.

Opportunities for innovation lie in areas such as:

- Developing energy-efficient plasma etching and deposition systems

- Adapting equipment for use with new semiconductor materials like gallium nitride and silicon carbide

- Implementing edge computing solutions within the equipment for faster decision-making

Investments in research and development, alongside collaboration between toolmakers and chip manufacturers, will be crucial in overcoming these hurdles. As technology nodes continue to shrink and performance expectations increase, the role of semiconductor processing equipment as a cornerstone of precision manufacturing will only become more significant.

Conclusion: Supporting Innovation Through Precision Equipment

For professionals engaged in semiconductor fabrication, the quality and capability of processing equipment directly influence product performance and business outcomes. From enabling cleaner production to supporting next-generation chip architectures, advanced manufacturing tools are critical assets in a highly competitive industry. Staying informed about technological advancements and investing in precision-focused solutions allows manufacturers to meet the growing demands of modern electronics while maintaining reliability, efficiency, and scalability in production.

Leave a Reply