The Fundamentals of Autoclave Technology

Autoclave Technology: Reliable Sterilization for Industrial Use relies on a process that combines high-pressure saturated steam and elevated temperatures to eliminate microorganisms from various materials. This method is widely recognized for its effectiveness and consistency, especially in environments where contamination control is critical. Autoclaves are commonly used in sectors such as pharmaceuticals, biotechnology, food processing, and manufacturing—each requiring dependable sterilization protocols to ensure product safety and compliance with industry standards.

At its core, the autoclaving process involves:

- Filling the chamber with steam under controlled pressure

- Maintaining specific temperature and pressure levels for a set duration

- Gradual depressurization and drying, depending on the load type

This method outperforms other sterilization techniques, such as dry heat or chemical exposure, particularly in terms of penetration and speed. Its ability to neutralize bacteria, viruses, fungi, and spores makes it a cornerstone of industrial hygiene strategies.

Applications Across Diverse Industries

Autoclave Technology: Reliable Sterilization for Industrial Use finds application in a wide variety of sectors beyond traditional medical and laboratory environments. In industrial settings, autoclaves contribute significantly to maintaining safety and quality control throughout production workflows. For instance, in the food industry, they are used to sterilize packaging materials and certain processed goods to extend shelf life without chemical preservatives.

In the manufacturing of medical devices, autoclaves ensure tools and components meet sterilization requirements before distribution. The electronics sector also benefits, particularly in cleanroom environments, where contamination can lead to product defects. Key applications include:

- Sterilization of reusable components and instruments

- Decontamination of laboratory waste and biological materials

- Preparation of growth media and culture solutions

- Sanitization of production line equipment

These diverse uses highlight the adaptability and reliability of autoclave systems across demanding industrial conditions.

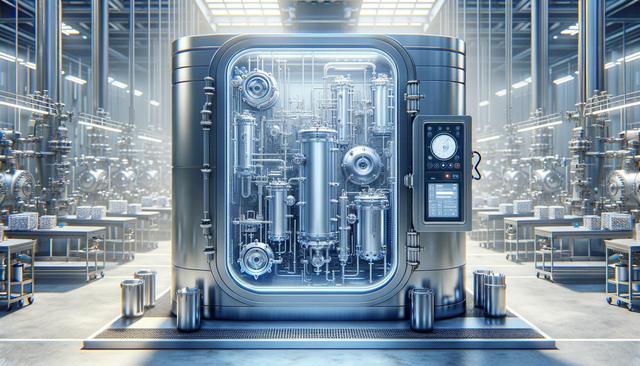

Types of Industrial Autoclaves

Autoclave Technology: Reliable Sterilization for Industrial Use is supported by a range of equipment types tailored to specific operational needs. Industrial autoclaves vary in design, size, and function depending on the volume and type of materials to be processed. Some of the most common types include:

- Gravity displacement autoclaves – suitable for non-porous items and liquids

- Pre-vacuum autoclaves – ideal for porous loads and wrapped instruments

- Horizontal and vertical chamber models – chosen based on space and load requirements

- Continuous sterilization systems – used in high-throughput manufacturing lines

Each type incorporates control systems that allow operators to monitor temperature, pressure, and cycle duration. Modern autoclaves are increasingly equipped with digital interfaces and automated reporting features, enhancing traceability and compliance with regulatory frameworks.

Efficiency, Safety, and Compliance Benefits

Autoclave Technology: Reliable Sterilization for Industrial Use offers not only reliable results but also operational benefits that support efficiency and workplace safety. By utilizing automated cycles and programmable settings, autoclaves reduce human error and free up labor for other tasks. Moreover, their sealed systems minimize exposure to potentially hazardous biological agents or chemicals.

From a regulatory standpoint, autoclaves help facilities meet stringent sterilization and documentation standards set by international bodies. Many industries require validation and regular performance testing, which autoclaves are well-equipped to support through built-in monitoring tools and audit-ready logs. Key benefits include:

- Consistent sterilization outcomes across batches

- Reduction in cross-contamination risks

- Improved process validation and record-keeping

- Low environmental impact compared to chemical alternatives

These advantages make autoclaves a sustainable and compliant choice for industrial sterilization processes.

Maintenance and Operational Considerations

To ensure the long-term reliability of Autoclave Technology: Reliable Sterilization for Industrial Use, regular maintenance and proper operational practices are essential. Like any precision equipment, autoclaves require periodic servicing to function optimally. This includes checking seals, safety valves, steam generators, and chamber integrity. Routine calibration and validation cycles also help maintain consistency and compliance.

Operators should be trained on correct loading techniques, cycle selection, and safety protocols to prevent issues such as incomplete sterilization or equipment damage. Implementing a preventive maintenance schedule can help avoid downtime and costly repairs. Common maintenance practices include:

- Inspecting gaskets and door locks for wear

- Cleaning the chamber and filters routinely

- Testing pressure and temperature sensors

- Updating software and cycle parameters as needed

Proper record-keeping of maintenance activities and cycle logs ensures traceability and supports audit readiness. These practices are particularly important in regulated industries where equipment performance directly impacts product safety and consumer trust.

Conclusion

Autoclave Technology: Reliable Sterilization for Industrial Use continues to be a vital asset across a broad range of industries. Its ability to deliver consistent and effective sterilization, combined with operational efficiency and regulatory compliance, makes it an integral part of modern industrial workflows. For businesses seeking dependable solutions for contamination control, investing in and maintaining autoclave systems can significantly enhance product quality, workplace safety, and process reliability.

Leave a Reply