Understanding the Role of Chemical Dosing Systems

Chemical Dosing Systems: Accurate Dispensing for Process Control plays a vital role in a wide range of industries by ensuring that the correct amount of chemicals is introduced into a process. These systems are designed to maintain consistency and reliability in dosing operations, which is essential for maintaining the quality and safety of the final product. Whether used in water treatment, food processing, pharmaceuticals, or manufacturing, the ability to deliver precise chemical quantities reduces risks and improves operational efficiency. These systems can be configured to handle various types of chemicals, including acids, alkalis, coagulants, and disinfectants, each with specific handling and safety requirements.

Advanced dosing systems are equipped with programmable logic controllers (PLCs), flow meters, and feedback loops that allow for real-time adjustments. These features help operators manage variations in process demand and chemical concentration. As a result, processes remain stable even under changing conditions. The technology also supports integration with broader process control systems, enabling centralized monitoring and data analysis that facilitates preventive maintenance and continuous improvement.

Benefits of Precision in Chemical Dispensing

Accuracy in chemical dosing translates directly into operational advantages. Chemical Dosing Systems: Accurate Dispensing for Process Control helps prevent overuse or underuse of chemicals, both of which can lead to costly consequences. Overdosing increases chemical consumption and waste, raises safety concerns, and may require additional treatment steps. Underdosing, on the other hand, can result in substandard product quality or ineffective process outcomes.

Some of the key benefits of precise dosing include:

- Improved process efficiency and product consistency

- Reduced chemical waste and associated costs

- Better regulatory compliance and environmental safety

- Lower maintenance requirements due to reduced scaling or corrosion

These advantages make chemical dosing systems an essential component of modern industrial operations, contributing to both economic and environmental sustainability.

Key Components of an Effective Dosing System

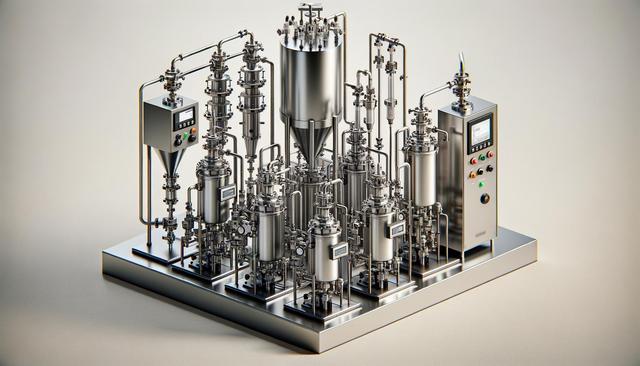

A well-designed Chemical Dosing Systems: Accurate Dispensing for Process Control setup consists of several integral components that work together to achieve precision. These typically include storage tanks, dosing pumps, control valves, sensors, and monitoring systems. Each component must be selected based on the specific characteristics of the chemical being used and the demands of the process environment.

Important elements to consider include:

- Material compatibility with the chemicals being dosed

- Flow rate requirements and viscosity of the fluids

- Accuracy tolerances and repeatability of the dosing process

- Ease of maintenance and availability of replacement parts

Proper system integration ensures that all components communicate effectively, reducing the risk of errors and inefficiencies. Automation also plays a significant role, enabling remote operation and reducing the need for manual intervention.

Applications Across Industrial Sectors

Chemical Dosing Systems: Accurate Dispensing for Process Control is utilized across diverse industries where precise chemical management is vital. In water and wastewater treatment, dosing systems ensure the correct amount of disinfectants, coagulants, and pH adjusters are introduced to maintain water quality. In food and beverage production, they help preserve product integrity and meet health standards by accurately introducing preservatives, flavorings, or sanitizing agents.

Other common applications include:

- Pharmaceuticals: Ensuring accurate formulation and compliance with stringent standards

- Power generation: Dosing corrosion inhibitors and boiler treatment chemicals

- Textile manufacturing: Controlling dye and chemical applications for consistent fabric quality

In each of these sectors, the reliability of dosing systems directly impacts product quality, safety, and regulatory compliance. Therefore, selecting the appropriate system design and technology is crucial for achieving desired outcomes.

Maintenance and Optimization Strategies

To ensure long-term performance, Chemical Dosing Systems: Accurate Dispensing for Process Control requires regular maintenance and periodic optimization. Preventive maintenance activities include inspecting seals and valves for wear, calibrating sensors, and ensuring pumps operate within specified parameters. Scheduled checks help prevent downtime and extend equipment lifespan.

Optimization strategies also involve monitoring key performance indicators (KPIs) such as chemical usage rates, dosing accuracy, and system response times. Data collected from integrated sensors and control systems can be analyzed to identify trends and potential issues before they impact operations. Implementing continuous improvement practices allows facilities to fine-tune their processes, reduce costs, and maintain high standards of safety and efficiency.

Training for operators and maintenance personnel is another important component. Ensuring that staff understand system functionality and safety protocols reduces the risk of human error and enhances overall system reliability. With the right combination of equipment, monitoring, and skilled personnel, chemical dosing systems can perform effectively and consistently over time.

Conclusion: Enhancing Process Control Through Precision

For industries that rely on accurate chemical application, Chemical Dosing Systems: Accurate Dispensing for Process Control offers a strategic advantage. These systems provide the precision, consistency, and reliability needed to support high-quality production and regulatory compliance. By integrating advanced technologies and implementing robust maintenance practices, businesses can improve efficiency, reduce waste, and ensure safe operations. As demand for sustainable and cost-effective solutions grows, investing in well-designed dosing systems becomes increasingly valuable for long-term success.

Leave a Reply