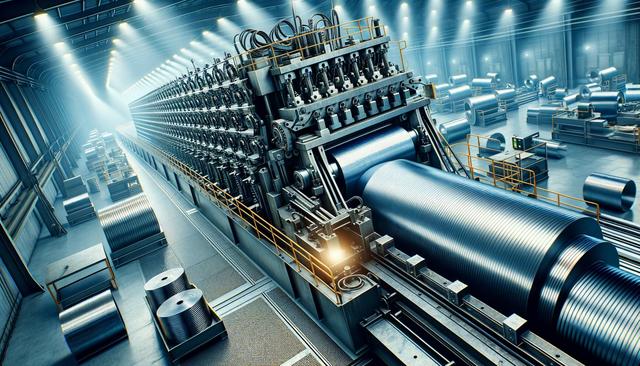

Understanding the Role of Coil Forming Machines in Industrial Manufacturing

In the realm of industrial manufacturing, precision and reliability are crucial, especially when it comes to producing components like coils for transformers and electric motors. Coil forming machines are specialized tools designed to shape and wind wire into precise configurations, ensuring high performance and consistency. These machines take raw wire material and apply controlled bending, shaping, and winding processes that meet strict industrial specifications. By automating this stage of production, coil forming machines not only improve accuracy but also contribute to faster production cycles and reduced waste.

The importance of coil forming machines becomes evident when considering their role in sectors such as power generation, automotive, aerospace, and manufacturing. Coils produced through these machines are integral to the operation of a wide array of devices, from compact transformers to large industrial motors. Without these machines, achieving the exacting standards required for coil geometry and insulation would be far more time-consuming and prone to error.

Key Features That Define Coil Forming Machine Performance

Modern coil forming machines are equipped with advanced features that enhance performance and adaptability in various production environments. These machines typically support a range of wire diameters and materials, including copper, aluminum, and specialty alloys. The core functions often include:

- Programmable control systems for customized coil patterns

- Integrated tension control to prevent wire deformation

- Automatic wire feeding and cutting for consistent outputs

- Precision tooling for forming complex coil geometries

Such features make it easier for manufacturers to maintain tight tolerances and ensure the longevity and efficiency of the final product. Additionally, many machines are designed with user-friendly interfaces and safety mechanisms, allowing operators to work efficiently while minimizing risk.

Applications Across Various Industrial Sectors

Coil forming machines find application in numerous industries where electromagnetic components are required. These include the production of:

- Power transformers for electrical grids

- Stator and rotor coils for electric motors

- Inductors and chokes for electronic circuits

- Custom coils for medical or scientific equipment

In each of these applications, the consistency and accuracy provided by coil forming machines play a key role in ensuring optimal performance. For instance, in electric vehicles, motor efficiency directly impacts energy consumption. High-quality stator coils formed with precision machines help meet stringent energy standards while also supporting innovation in compact and lightweight motor designs.

Precision and Automation: A Competitive Advantage

The use of coil forming machines provides manufacturers with a distinct competitive advantage by improving production efficiency and product quality. Automation reduces the need for manual labor, minimizes human error, and enables scalable production. This is particularly valuable in industries where demand fluctuates or where customization of coil specifications is frequently required.

Moreover, the precision achieved through these machines ensures that each coil meets exact design parameters, which is essential for maintaining the integrity of high-performance electrical equipment. The ability to quickly switch between different coil designs and wire types further enhances operational flexibility, allowing manufacturers to respond to market needs more effectively.

Maintenance and Operational Considerations

To maximize the longevity and performance of coil forming machines, regular maintenance is essential. This includes routine inspections, software updates for programmable systems, and periodic calibration of forming tools. Proper training for operators is also critical to ensure safe and efficient use of the machinery.

Manufacturers typically implement preventive maintenance schedules that involve:

- Cleaning and lubricating moving parts

- Checking electrical connections and power systems

- Replacing worn or damaged components

- Monitoring system diagnostics and error logs

By investing in these practices, organizations can reduce downtime, avoid costly repairs, and ensure that the machines continue to produce high-quality coils with consistent precision.

Conclusion: Investing in Coil Forming Machines for Sustainable Growth

For manufacturers in sectors that rely on high-quality electromagnetic components, coil forming machines represent a valuable investment. Their ability to deliver accurate, repeatable results while supporting a range of coil configurations makes them indispensable in modern production environments. By improving efficiency, enabling automation, and ensuring product consistency, these machines help businesses stay competitive and meet evolving industry demands. Whether for large-scale industrial transformers or compact motor systems, coil forming machines provide the shaping precision required to support innovation and reliability in today’s technology-driven world.

Leave a Reply