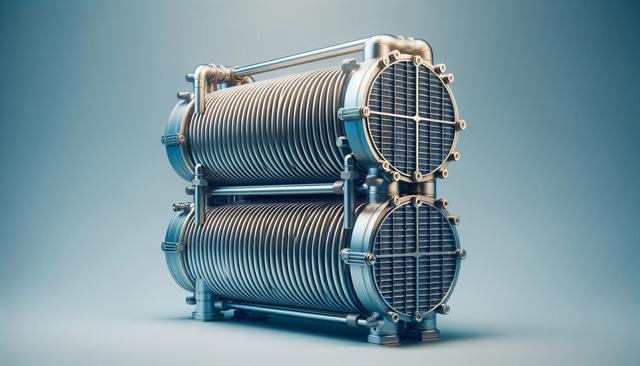

Understanding the Structure of Finned Double Pipe Heat Exchangers

Finned double pipe heat exchangers are a type of indirect heat exchange equipment known for their ability to enhance thermal transfer, particularly in systems where there is a significant temperature difference between two fluids. The design includes two concentric pipes: one fluid flows through the inner pipe while the second fluid flows through the annular space between the pipes. What makes this type of heat exchanger distinctive is the addition of fins, typically on the exterior of the inner pipe, which serve to increase the surface area available for heat exchange. The increase in surface area allows for more effective thermal transfer, especially in applications where space efficiency and performance are critical.

These fins can be either integral (machined as part of the pipe) or attached (fixed onto the pipe surface), and they help dissipate or absorb heat at a faster rate than would be possible with a smooth pipe alone. Materials commonly used include stainless steel, copper, and various alloys, selected based on the thermal conductivity required, compatibility with fluids, and resistance to corrosion. This structural advantage makes finned double pipe heat exchangers a preferred option in many industrial settings.

Key Advantages of Finned Double Pipe Heat Exchangers

The finned double pipe heat exchanger offers several strengths that make it a reliable choice for demanding thermal management scenarios. One of its greatest benefits is its compact size relative to its capacity for heat transfer, which is achieved through the use of fins. This allows for installation in facilities where space is at a premium without compromising performance.

Other notable advantages include:

- Enhanced thermal efficiency: The fins increase the surface area, resulting in better heat transfer rates.

- Ease of maintenance: The modular nature of the design allows for straightforward cleaning and inspection.

- Flexibility: Suitable for both heating and cooling applications across various fluid types.

- Durability: Can be built using corrosion-resistant materials, ensuring long-term operation in harsh environments.

These features collectively support cost-effective operation over the lifespan of the equipment, making it an advantageous solution for applications involving large temperature gradients.

Typical Applications Across Industries

Finned double pipe heat exchangers are utilized in a wide range of industries due to their adaptability and performance. They are particularly valuable in systems where one fluid must be brought to a significantly different temperature in a relatively short time. For instance, in the chemical processing industry, they are used to either cool down exothermic reaction mixtures or heat up reactants to required temperatures before entering a reactor.

Common sectors where these heat exchangers are deployed include:

- Oil and gas: Used in preheating crude oil or cooling down process fluids before separation stages.

- Power generation: Employed in managing heat loads in turbines and condensers.

- HVAC systems: Utilized in heating and cooling loops for buildings and industrial facilities.

- Food and beverage: Applied in pasteurization processes and CIP systems for maintaining hygiene standards.

Each of these applications benefits from the exchanger’s efficiency and ability to handle significant thermal differentials without requiring extensive infrastructure.

Factors to Consider When Selecting a Finned Double Pipe Heat Exchanger

Choosing the appropriate finned double pipe heat exchanger involves evaluating several key parameters. The primary consideration is the temperature range and thermal load expected in the application. Depending on whether the system requires more intensive heating or cooling, the size and type of fins, as well as the materials used, will vary.

Other factors to assess include:

- Fluid compatibility: Ensuring that the materials used in the exchanger are chemically compatible with the fluids involved.

- Pressure ratings: The design must accommodate the expected pressure within the system without the risk of failure.

- Maintenance access: Systems with accessible components facilitate easier servicing and reduce downtime.

- Installation space: The available space in the facility may dictate specific size and orientation requirements.

Proper sizing and configuration are critical, as an undersized exchanger may not meet thermal performance goals, while an oversized unit could lead to unnecessary capital expenditure.

Operational Efficiency and Performance Optimization

To ensure that a finned double pipe heat exchanger operates at its highest potential, regular maintenance and performance evaluations are essential. Over time, fouling on the fins or internal surfaces can reduce thermal conductivity and overall efficiency. Cleaning schedules and inspection routines should be established based on operating conditions and the type of fluids used.

Performance can also be optimized through:

- Flow rate control: Adjusting the flow rates of both fluids to maintain favorable thermal gradients and avoid flow-induced vibrations.

- Temperature monitoring: Implementing sensors to track inlet and outlet temperatures helps identify potential performance issues early.

- Material upgrades: Retrofitting older units with improved materials or fin designs can enhance durability and performance.

By incorporating these strategies, facilities can extend the operational life of their heat exchangers and maintain high levels of energy efficiency in their thermal systems.

Conclusion: Why Finned Double Pipe Heat Exchangers Remain a Valuable Choice

For industries requiring reliable thermal control under conditions with large temperature differences, finned double pipe heat exchangers present a compelling solution. Their structural design, enhanced by fins for greater heat exchange surface area, supports efficient and consistent performance across various applications. From chemical processing to power generation, these heat exchangers offer a well-regarded balance of efficiency, adaptability, and maintainability.

When chosen and maintained properly, they contribute significantly to operational efficiency, energy conservation, and system reliability. Engineers and facility managers seeking dependable heat transfer systems will find finned double pipe heat exchangers to be a practical and effective component in achieving their thermal management goals.

Leave a Reply