Understanding the Role of the Gasoline Engine

The gasoline engine is the driving force behind many portable and stationary generators. This type of internal combustion engine converts the chemical energy in gasoline into mechanical energy through a series of controlled explosions. These explosions occur within the engine’s cylinders when a mixture of fuel and air is ignited by a spark plug. The resulting force moves pistons, which in turn rotate the engine’s crankshaft. This rotational energy is what eventually powers the generator. Gasoline engines are popular due to their availability, ease of use, and relatively low maintenance needs. They are especially useful in portable applications due to their compact size and efficiency in delivering power quickly and reliably.

How the Generator Converts Mechanical Energy to Electricity

Once the gasoline engine is running and producing mechanical energy, the generator takes over the task of converting this energy into electrical power. The generator consists of several key components, including the rotor, stator, and voltage regulator. The rotor, connected to the engine’s crankshaft, spins within the stator, a stationary coil of wire. As the rotor turns, it creates a magnetic field that induces an electrical current in the stator windings. This process, known as electromagnetic induction, is what generates electricity. The voltage regulator then ensures that the output voltage remains stable, regardless of changes in load or engine speed. This seamless conversion process is what allows gasoline-powered generators to supply consistent and usable electricity to homes, tools, or electronic devices.

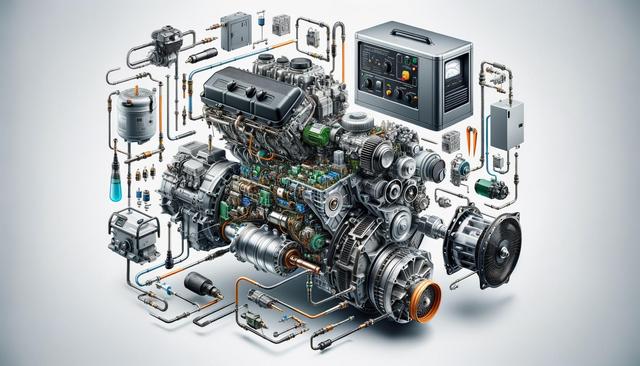

Integration of Engine and Generator Systems

The seamless operation of a gasoline engine and generator combination relies heavily on their integration. These systems are designed to work in tandem, with the engine providing the precise amount of mechanical power needed for the generator to produce electricity at the desired output. The entire unit often comes encased in a single housing, which includes the fuel tank, cooling system, exhaust system, and control panel. Key factors that ensure efficient integration include:

- Proper engine-to-generator alignment to reduce mechanical losses

- Effective cooling to prevent overheating during extended use

- Vibration dampening to protect internal components

- Automated controls for starting, stopping, and monitoring performance

This level of integration not only maximizes efficiency but also simplifies operation for users, making gasoline-powered generators a practical solution for a variety of energy needs.

Common Applications of Gasoline Engine Generators

Gasoline engine generators are used in a variety of settings, providing flexible and dependable power where and when it’s needed most. Their portability and relatively quiet operation make them especially suited for temporary or emergency use. Common applications include:

- Emergency backup power during electrical outages

- Power supply for outdoor events and recreational activities

- Support for construction sites without grid access

- Energy source for remote cabins or off-grid living

Because they are easy to transport and set up, gasoline engine generators are also favored by travelers, campers, and mobile service providers. Their varied uses demonstrate the versatility of these machines in both residential and commercial contexts.

Maintenance and Safety Considerations

Maintaining a gasoline engine generator is essential for reliable performance and safety. Regular checks and timely servicing ensure the longevity of the machine and reduce the risk of operational failures. Key maintenance tasks include:

- Changing the engine oil at recommended intervals

- Replacing or cleaning air and fuel filters

- Inspecting spark plugs for wear or damage

- Checking fuel quality and avoiding stale gasoline

- Ensuring the cooling system is functioning properly

Safety is equally important when using gasoline-powered equipment. Users should always operate generators in well-ventilated areas to prevent carbon monoxide buildup and should follow manufacturer guidelines for load management and electrical connections. Additionally, storing gasoline safely and handling it with care helps prevent accidents and extends the life of the engine.

Conclusion

Gasoline engine and generator systems offer a practical solution for individuals and businesses needing temporary or emergency power. By understanding how these machines work together—from the internal combustion process to the generation of electricity—users can make informed decisions about operation, maintenance, and application. Whether supplying backup power at home or running tools at a remote site, this combination provides a dependable energy source when grid access is limited or unavailable.

Leave a Reply