Understanding the Role of Industrial Reverse Osmosis Systems for Water Purification

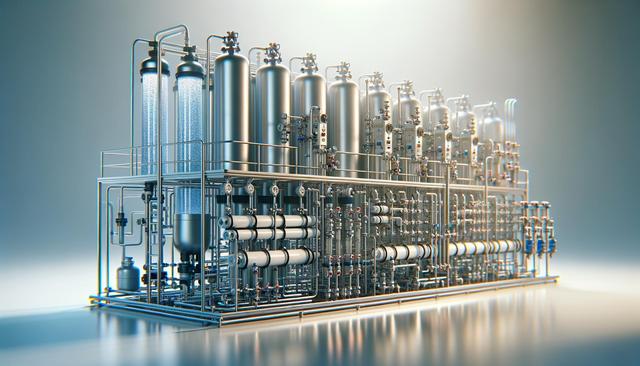

Industrial Reverse Osmosis Systems for Water Purification are engineered to handle large-scale water treatment requirements across various sectors. These systems work by applying pressure to force water through semi-permeable membranes, effectively removing dissolved salts, organic compounds, and other contaminants. The result is purified water that meets stringent industrial standards. This process is particularly valuable in industries such as food and beverage production, pharmaceuticals, energy generation, and chemical manufacturing, where water quality directly impacts product consistency, safety, and operational efficiency.

One of the core advantages of Industrial Reverse Osmosis Systems for Water Purification is their ability to reduce total dissolved solids (TDS) to extremely low levels. This is essential for applications that require ultrapure water, such as laboratory processes or cooling tower operations. Additionally, these systems contribute to sustainable water use by enabling the reuse and recycling of process water, which can significantly lower overall consumption and environmental impact.

Key Components and Functionality

Industrial Reverse Osmosis Systems for Water Purification consist of several critical components that work together to ensure optimal performance. Each part plays a specific role in the filtration and purification process, contributing to the system’s overall reliability and efficiency. The main components include:

- Pre-treatment units (such as multimedia filters and water softeners) to remove larger particulates and chlorine

- High-pressure pumps to push water through the reverse osmosis membranes

- RO membranes that filter out dissolved impurities

- Post-treatment options for pH adjustment or remineralization, depending on application needs

- Control panels and monitoring systems for real-time performance tracking

The precision of these components allows for consistent output, even when dealing with fluctuating water quality or variable flow rates. Automation and smart monitoring features have become increasingly common, allowing operators to respond quickly to maintenance needs or performance deviations.

Applications Across Different Industries

Industrial Reverse Osmosis Systems for Water Purification are used in a wide range of industries that rely on clean water for their processes. These systems are not limited to any one sector, making them a versatile solution for many high-demand environments. Common applications include:

- Food and beverage processing for ingredient water and cleaning systems

- Pharmaceutical manufacturing where high-purity water is essential

- Power plants that require demineralized water for boilers and cooling systems

- Textile and dye industries for rinsing and dyeing operations

- Electronics and semiconductor production requiring ultrapure water for fabrication

Each of these industries benefits from the scalable nature of Industrial Reverse Osmosis Systems for Water Purification, which can be customized to meet specific flow rates, purity levels, and regulatory requirements.

Benefits of Implementing Industrial Reverse Osmosis Systems

Investing in Industrial Reverse Osmosis Systems for Water Purification offers several practical and long-term benefits for businesses. These advantages go beyond water quality and touch on cost savings, regulatory compliance, and operational sustainability. Some of the key benefits include:

- Significant reduction in chemical usage for water treatment

- Lower energy consumption compared to thermal desalination technologies

- Decreased equipment corrosion and scaling, extending machinery lifespan

- Improved compliance with environmental discharge regulations

- Enhanced water reuse potential leading to reduced freshwater dependency

These systems also support corporate sustainability goals by minimizing the environmental footprint of industrial operations. As industry standards continue to evolve, having a reliable purification system in place becomes a strategic asset.

Maintenance and Operational Considerations

Although Industrial Reverse Osmosis Systems for Water Purification are designed for reliability, regular maintenance is essential to ensure consistent performance. Maintenance routines typically include membrane cleaning, replacement of pre-filters, and periodic system inspections. Operational staff should be trained to recognize signs of membrane fouling or scale buildup, which can impact efficiency and water quality.

To support long-term system health, companies often implement preventive maintenance plans that include:

- Scheduled membrane integrity testing

- Monitoring of flow rates and pressure differentials

- Software updates for automated control systems

- Water quality testing at various stages of the process

With proper care, Industrial Reverse Osmosis Systems for Water Purification can deliver high-quality water consistently over many years, providing a strong return on investment and operational resilience.

Conclusion: Supporting Industrial Efficiency Through Reliable Water Purification

Industrial Reverse Osmosis Systems for Water Purification play a vital role in helping companies meet their water quality requirements while enhancing operational efficiency. By delivering purified water at scale, these systems support critical processes in industries where consistency, safety, and regulatory compliance are non-negotiable. For organizations seeking robust, scalable, and environmentally responsible water treatment solutions, investing in such systems is a forward-looking choice that aligns with both business goals and sustainability commitments.

Leave a Reply