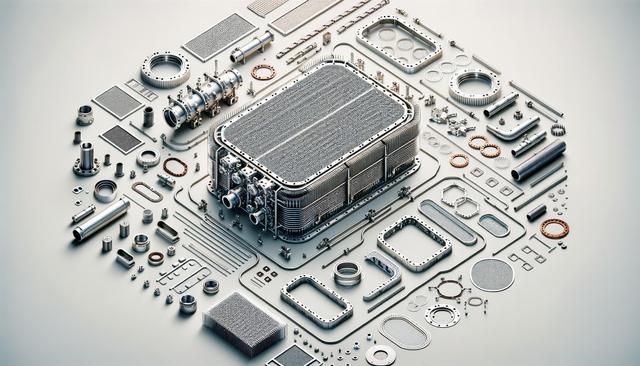

Understanding Plate Heat Exchanger Technology

Plate heat exchangers are widely used in industries such as HVAC, chemical processing, food and beverage, and power generation due to their compact design and high efficiency. These systems consist of multiple thin, corrugated plates that create channels for hot and cold fluids to flow through in alternate layers. The heat is transferred between the fluids through the plates without mixing them. This design enables precise temperature control and energy efficiency, which are critical for both industrial operations and climate control systems. As demand grows for energy-efficient thermal management, the role of plate heat exchanger manufacturers becomes increasingly important in providing reliable and customized solutions.

Manufacturers often differentiate their products based on factors such as plate material, gasket type, frame design, and maintenance requirements. For example, stainless steel plates are commonly used for their durability and corrosion resistance, while titanium plates may be preferred in more aggressive chemical environments. Understanding these technical aspects is essential when comparing different manufacturers, as it ensures compatibility with specific application needs.

Key Features to Compare Among Manufacturers

When evaluating plate heat exchanger manufacturers, it’s important to consider several key features that directly impact performance and long-term value. These features not only determine the efficiency of the equipment but also its adaptability to different operating environments. Some of the primary aspects to compare include:

- Thermal performance: Efficiency in heat transfer, influenced by plate design and flow arrangement.

- Material options: Availability of stainless steel, titanium, or other specialized alloys.

- Ease of maintenance: Design elements that simplify cleaning and gasket replacement.

- Scalability: Ability to expand the system as process demands grow.

- Customization: Options for tailoring plate count, size, and configuration to specific applications.

Manufacturers that offer a wide range of configurations and material choices are typically better equipped to meet unique industry requirements. Furthermore, the availability of engineering support and guidance during the selection process can significantly impact the success of a project.

Applications Across Industries

Plate heat exchangers are used in a diverse array of applications, and manufacturers often specialize in serving specific sectors. In HVAC systems, they are used for heat recovery, district heating, and chilled water loops. In the food and beverage industry, they support pasteurization and fermentation processes by ensuring sanitary thermal transfer. Chemical and pharmaceutical industries rely on them for controlled heating and cooling where precise temperature regulation is crucial.

Each industry presents unique challenges, such as pressure rating, fluid compatibility, and regulatory compliance. Therefore, choosing a manufacturer with proven experience in your specific sector can be beneficial. Look for companies that provide:

- Case studies or references from similar applications

- Certifications relevant to your industry standards

- Technical documentation and performance data

This ensures that the equipment not only meets operational requirements but also aligns with safety and regulatory expectations.

Manufacturing Standards and Innovations

Quality and innovation are central to the offerings of leading plate heat exchanger manufacturers. Many invest in research and development to improve plate geometries, flow distribution, and gasket integrity. These innovations lead to better performance, longer service life, and reduced operational costs. Manufacturers may also follow international quality standards such as ISO 9001 for quality management or ASME standards for pressure vessels, which can serve as indicators of product reliability and consistency.

Additional technological advancements from manufacturers may include:

- Energy-efficient plate patterns that minimize pressure drop

- Tool-free gasket replacement systems

- Digital monitoring options for predictive maintenance

Manufacturers that actively invest in these areas can offer more advanced and user-friendly solutions. These innovations often translate into real operational savings and enhanced system uptime, making them valuable considerations during the selection process.

After-Sales Support and Service

After-sales service is another critical factor when evaluating plate heat exchanger manufacturers. High-quality support ensures that the system remains efficient and reliable over time. Services can include installation assistance, routine inspections, spare parts availability, and emergency response for repairs. Manufacturers with a strong global presence or local service networks tend to offer more responsive and accessible support.

Key aspects to look for in a manufacturer’s service offering include:

- Availability of replacement gaskets and plates

- On-site maintenance and troubleshooting

- Training programs for operators and maintenance staff

- Warranty terms and technical support availability

Reliable after-sales service not only extends the lifespan of the equipment but also minimizes downtime and unexpected costs. It’s advisable to assess the manufacturer’s service reputation and support infrastructure as part of the selection process.

Conclusion: Choosing the Right Manufacturer

For businesses seeking dependable and efficient thermal management solutions, selecting the right plate heat exchanger manufacturer is a critical decision. By comparing technical features, industry expertise, innovation, and after-sales support, buyers can make more informed choices that align with their operational needs. Manufacturers that offer a combination of technical excellence, customization options, and responsive service are well-positioned to deliver long-term value. Whether for industrial processing or HVAC applications, partnering with a reputable and well-regarded manufacturer helps ensure optimal performance and reliability of your thermal systems.

Leave a Reply