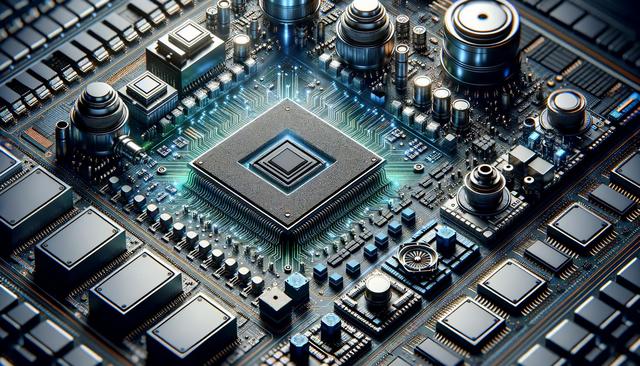

Semiconductor Equipment Landscape in Ireland

Ireland has emerged as a significant hub for semiconductor development in Europe, with a growing ecosystem that supports chip design, manufacturing, and testing. The availability of advanced semiconductor equipment in Ireland supports both multinational corporations and local startups involved in integrated circuit (IC) production. In particular, fab tools in Dublin have seen increased demand due to the presence of fabrication facilities that require high-precision tools for wafer etching, ion implantation, and chemical vapor deposition.

The country’s infrastructure supports various stages of semiconductor fabrication, notably:

- Front-end wafer processing for logic and memory chips

- Back-end assembly and packaging solutions

- Advanced testing and validation equipment

As clean manufacturing standards are essential, cleanroom tools in Ireland have become a critical component of the industry. These tools maintain contamination-free environments essential for nanometer-scale processes. With Ireland’s strategic role in the global supply chain, continued investment in wafer processing in Ireland ensures alignment with the latest technological nodes and stringent industry requirements.

Semiconductor Innovation and Infrastructure in France

France plays a central role in Europe’s semiconductor sector, particularly in research and development. The country’s focus on innovation is evident in its support for microelectronics and nanotechnology clusters. Key production facilities across France utilize cutting-edge semiconductor France technologies that encompass both device fabrication and materials engineering.

French semiconductor infrastructure supports a wide range of applications including automotive electronics, telecommunications, and power management. The variety of tools in use includes:

- Deposition systems for thin-film creation

- Etching tools for micro-patterning

- Packaging and testing equipment for finished ICs

Cleanroom facilities in France are equipped with high-precision instruments that align with international standards for micro-contamination control. This is particularly relevant for the fabrication of high-reliability components used in aerospace and defense. As European demand for advanced chips grows, France remains a key player in supporting scalable and resilient semiconductor production.

Germany’s Advanced Lithography and Process Tools

Germany is renowned for its strength in industrial engineering, and this extends into the semiconductor sector, especially in lithographic and process control technologies. The use of lithography tools in Germany is central to achieving the miniaturization required for state-of-the-art ICs. These tools are fundamental in defining intricate circuit patterns on silicon wafers.

In addition to lithography, Germany hosts a wide range of process chambers in Europe, which are essential for steps like atomic layer deposition, plasma etching, and oxidation. These chambers are integrated into fully automated production lines that enable high throughput and consistent quality.

Germany’s contributions to the European chip supply chain include:

- High-precision optics for EUV lithography

- Automated wafer handling solutions

- Metrology tools for in-line inspection

With a strong emphasis on sustainability, German semiconductor companies are also leading the charge in energy-efficient and environmentally responsible manufacturing equipment, ensuring the long-term viability of the industry.

Switzerland’s Role in IC Manufacturing Equipment

Though smaller in scale compared to its neighbors, Switzerland is a notable contributor to Europe’s semiconductor landscape, especially in precision engineering and analytical equipment. IC manufacturing in Switzerland benefits from the country’s expertise in micro-mechanics and automation, which are essential for high-yield semiconductor fabrication.

Swiss innovation supports niche applications such as:

- Wafer bonding and dicing systems

- Advanced sensor integration tools

- Precision thermal management equipment

Companies in Switzerland often collaborate with European research institutions to develop prototype equipment that later scales into full production tools. These efforts support both traditional silicon-based ICs and emerging technologies such as compound semiconductors and MEMS.

With its focus on quality and reliability, Switzerland enhances Europe’s ability to produce highly specialized semiconductor components used in medical devices, aerospace, and industrial automation.

Outlook for Chip Equipment Across Europe

Throughout Europe, the semiconductor industry is undergoing a period of strategic growth fueled by increasing demand for local manufacturing capabilities. From chip equipment in Europe to high-performance cleanroom systems, countries like Ireland, France, Germany, and Switzerland are making significant investments in infrastructure and technology.

Europe’s equipment ecosystem is characterized by:

- Strong collaboration between public institutions and private industry

- Focus on high-value, low-volume production for specialized markets

- Ongoing development of tools for next-generation semiconductor nodes

As the global supply chain continues to evolve, the availability and advancement of semiconductor equipment in key European countries will play a vital role in ensuring competitive, secure, and sustainable chip manufacturing capabilities.

Conclusion: Supporting Europe’s Semiconductor Future

For stakeholders involved in semiconductor development, Europe presents a vibrant environment supported by world-class equipment and facilities. From fab tools in Dublin to lithography tools in Germany and IC manufacturing in Switzerland, the continent offers a diverse range of capabilities that cater to both established and emerging segments of the industry. Whether you’re involved in research, manufacturing, or systems integration, understanding the scope and availability of semiconductor tools across countries like Ireland, France, and Germany is essential for building resilient and future-ready operations.

Leave a Reply