Understanding the Role of Soybeans in Biodiesel Production

Soybeans have become a central crop in the push for sustainable energy solutions, particularly in the production of biodiesel. As a legume rich in oil content, soybeans are widely cultivated not only for food and feed but also for their high oil yield, which makes them suitable for biofuel processing. The extracted soybean oil serves as a crucial feedstock in the transesterification process, which converts vegetable oils into biodiesel. This renewable biofuel has gained traction as an alternative to conventional diesel, reducing greenhouse gas emissions and dependency on fossil fuels.

The popularity of soy-based biodiesel lies in the crop’s availability and relatively efficient oil extraction potential. Beyond environmental benefits, the use of soybeans in biofuel production supports agricultural economies and encourages sustainable farming practices. With the right processing equipment, producers can achieve high oil recovery rates, making economically scalable biodiesel production more feasible.

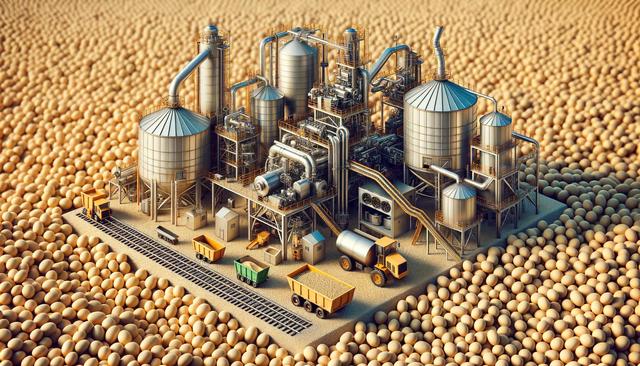

Key Stages in Soybean Processing for Biodiesel

The transformation of soybeans into biodiesel involves several stages, each relying on specific machinery to ensure efficiency and quality. The process begins with cleaning and dehulling, followed by oil extraction, purification, and eventually transesterification. Each step plays a vital role in ensuring that the resulting biodiesel meets industry standards for fuel quality.

Typical stages and equipment include:

- Cleaning and Dehulling Machines: Remove impurities and separate hulls from the soybean kernels.

- Oil Expellers or Presses: Mechanically extract oil from the dehulled beans.

- Solvent Extraction Units: Increase oil yield by using chemical solvents like hexane.

- Degumming and Neutralizing Systems: Remove unwanted compounds like phospholipids and free fatty acids.

- Transesterification Reactors: Convert the purified oil into biodiesel using methanol and a catalyst.

Each machine must be calibrated for optimal performance to ensure that the oil quality remains high throughout the process. The type and scale of machinery used can significantly influence overall production efficiency and cost-effectiveness.

Types of Soybean Processing Machines Used

There is a wide array of machinery available for soybean processing, designed to handle various production capacities and processing methods. Choosing the right equipment depends on factors such as production volume, desired oil yield, and available technology. Some machines are designed for cold pressing, which preserves more nutrients but yields less oil, while others are built for high-capacity solvent extraction.

Common machine types include:

- Integrated Soybean Oil Processing Units: Combine multiple operations such as cleaning, pressing, and filtering into a single machine, suitable for small to medium-scale producers.

- Industrial Solvent Extraction Plants: Designed for large-scale operations, offering higher oil recovery rates.

- Automated Transesterification Systems: Ensure consistent biodiesel quality through precise control of chemical reactions.

- Batch and Continuous Flow Reactors: Allow flexibility in production depending on scale and processing needs.

These machines often incorporate advanced features like digital monitoring, safety mechanisms, and energy-saving technologies. Adopting the right equipment not only improves productivity but also ensures compliance with environmental and safety regulations.

Challenges in Soybean-Based Biodiesel Processing

While soybean processing for biodiesel presents many opportunities, it also comes with challenges that producers must consider. One of the primary concerns is the cost of equipment and maintenance. High-quality processing machines can be capital-intensive, and regular maintenance is essential to avoid downtime and ensure consistent output. Additionally, the efficiency of oil extraction can vary depending on bean quality, moisture content, and the technology used.

Other challenges include:

- Feedstock Variability: Differences in soybean varieties can affect oil content and processing requirements.

- Energy Consumption: Some processes, particularly solvent extraction, can be energy-intensive.

- Waste Management: Proper disposal or utilization of by-products like soybean meal and glycerol is necessary to minimize environmental impact.

- Regulatory Compliance: Biodiesel producers must adhere to fuel quality standards and environmental regulations, requiring consistent monitoring and testing.

Overcoming these challenges often involves investing in modern, efficient machines and implementing quality control measures throughout the production process. Training staff to operate and maintain equipment also plays a crucial role in maximizing productivity and ensuring operational safety.

Opportunities and Future Outlook for Soybean Processing Equipment

As global interest in renewable energy sources increases, the demand for biodiesel is expected to grow, creating more opportunities for investment in soybean processing technology. Innovations in mechanical and chemical engineering are making machines more efficient, cost-effective, and environmentally friendly. From automation to energy recovery systems, the future of soybean processing machinery looks promising.

Some emerging trends include:

- Smart Processing Systems: Use sensors and AI to monitor operations and optimize efficiency in real time.

- Modular Equipment Designs: Allow producers to scale operations by adding or upgrading specific components.

- Hybrid Processing Technologies: Combine mechanical and chemical extraction methods for improved oil recovery.

- Eco-Friendly Solutions: Focus on reducing emissions, waste, and energy consumption throughout the processing chain.

These advancements make it easier for both small-scale farmers and large industrial producers to enter the biodiesel market or expand existing operations. Investing in the right soybean processing machines can be a long-term asset, supporting sustainable energy goals and contributing to a more circular agricultural economy.

Conclusion

The use of soybeans in biodiesel production offers a sustainable and practical approach to addressing energy challenges. By leveraging advanced soybean processing machines, producers can improve efficiency, reduce waste, and meet growing demand for cleaner fuels. Whether you’re a small-scale farmer or an industrial biodiesel producer, understanding the machinery involved and the opportunities they bring is key to successful and responsible biodiesel manufacturing. As technology continues to evolve, investing in modern processing equipment will remain a strategic move toward a more sustainable energy future.

Leave a Reply