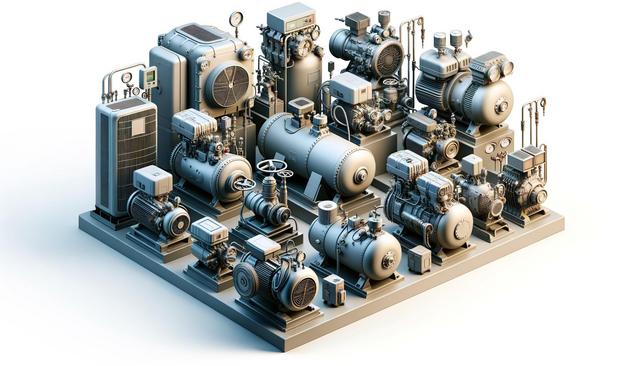

Understanding the Role of Air Compressors and Pumps

Air compressors and pumps play an essential role across a wide range of industries. They are used in manufacturing, construction, automotive repair, agriculture, and even in residential settings. The primary function of air compressors is to convert power into potential energy stored in pressurized air, which can then be used to power tools, inflate tires, or operate machinery. Pumps, on the other hand, serve to move fluids, including air, water, and oil, from one place to another. Understanding the specific requirements of a project or operation is the first step in identifying which type of equipment—and by extension, which supplier—is most suitable. The choice of equipment directly affects productivity and operational costs, making it imperative to choose a supplier that offers dependable and efficient solutions.

Key Factors to Consider When Choosing a Supplier

When evaluating air compressor and pump suppliers, several factors should be taken into account to ensure a smart investment. A reliable supplier offers not only quality products but also long-term service and support. Here are some key considerations:

- Product Range: Look for suppliers with a broad inventory of air compressors and pumps to meet various application needs.

- Technical Support: Availability of expert guidance on product selection, installation, and maintenance.

- After-Sales Services: Access to spare parts, repair services, and warranties.

- Certifications and Standards: Ensure products meet industry standards for safety and performance.

- Customer Reviews: Feedback from other businesses or individuals can provide valuable insight into the supplier’s reliability and service quality.

Balancing these factors will help in identifying suppliers who not only provide equipment but also contribute to operational efficiency and long-term value.

Types of Air Compressors and Pumps Offered

Understanding the types of equipment available can also guide your choice of supplier. Leading suppliers typically offer a wide assortment, including:

- Reciprocating (Piston) Air Compressors: Ideal for intermittent use in smaller workspaces.

- Screw Compressors: Designed for continuous operation and commonly used in industrial environments.

- Centrifugal Compressors: Suitable for very high capacity operations with stable demand.

- Diaphragm Pumps: Great for handling hazardous or corrosive fluids.

- Centrifugal Pumps: Common in water supply and HVAC systems.

- Submersible Pumps: Used for draining water in construction and mining.

Suppliers with a comprehensive catalog are often better positioned to meet the unique demands of different industries and projects, enabling customers to find tailored solutions under one roof.

Industries Served by Air Compressor and Pump Suppliers

Top-tier suppliers usually cater to a diverse set of industries, offering solutions that match specific environmental conditions and operational requirements. Some of the main industries include:

- Manufacturing: For powering pneumatic tools and automation systems.

- Construction: Equipment for site preparation, pneumatic tools, and dewatering.

- Automotive: Compressors for spray painting, tire inflation, and mechanical repairs.

- Agriculture: Pumps for irrigation, chemical spraying, and waste management.

- Oil and Gas: Heavy-duty compressors and pumps for extraction and processing.

Suppliers that demonstrate a deep understanding of these industry-specific needs can offer more suitable, durable, and efficient options for end-users.

Evaluating Supplier Reputation and Support Services

While product specifications are important, the supplier’s reputation and the quality of their support services can be just as critical. A reputable supplier will not only deliver equipment but also ensure it integrates smoothly into your operations. Look for the following:

- Longevity in the Market: Suppliers with years of experience often have more refined processes and customer service models.

- Technical Training and Resources: Access to manuals, training sessions, and on-site guidance.

- Service Network: Availability of service centers or mobile technicians for ongoing maintenance.

- Customization Services: Ability to modify products to meet specific operational needs.

These aspects contribute to a more seamless experience, reducing downtime and ensuring the equipment performs optimally over its lifespan. Building a long-term relationship with a well-regarded supplier can be a strategic advantage for any business or individual user.

Conclusion: Making an Informed Supplier Choice

Choosing the right air compressor and pump supplier is more than a transactional decision—it’s a strategic one. Whether you’re managing an industrial operation or working on a personal project, the quality and reliability of your equipment depend heavily on the expertise and support of your supplier. By focusing on factors such as product variety, industry relevance, after-sales service, and overall reputation, you can find a partner that not only meets your current needs but also supports your long-term goals. Taking the time to evaluate suppliers thoroughly ensures that your investment delivers consistent performance and value across every application.

Leave a Reply