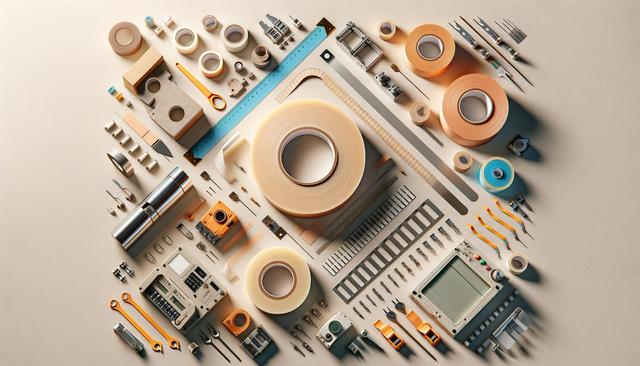

Understanding Carrier Tape in Electronics Packaging

Carrier tape plays a vital role in the efficient and secure transport of electronic components during the manufacturing and assembly processes. These tapes are engineered to hold components such as integrated circuits (ICs), resistors, capacitors, and other small parts in place, ensuring they remain protected from physical damage and electrostatic discharge (ESD). The carrier tape is typically used in conjunction with a cover tape and wound onto reels for automated handling. This combination is widely adopted in surface-mount technology (SMT) for high-volume electronics production.

Modern carrier tapes are designed with precision to accommodate a wide range of component sizes and shapes. The pockets formed in the tape are custom-molded or embossed to provide a snug fit for each type of component. Choosing the right type of carrier tape is essential for maintaining the integrity of delicate electronics, especially when they are shipped across long distances or handled by automated pick-and-place machines.

Key Criteria in Choosing a Carrier Tape Supplier

When selecting a carrier tape supplier, electronics manufacturers need to consider several critical factors to ensure optimal performance and reliability. Quality, consistency, and customization are among the most important attributes. A dependable supplier should be able to provide:

- High dimensional accuracy to ensure compatibility with automated systems

- Material compliance with industry standards such as ESD protection and RoHS

- Customization capabilities to produce tapes for non-standard components

- Reliable delivery schedules to support production timelines

In addition to technical specifications, the supplier’s ability to provide comprehensive support and documentation, including datasheets and compliance certifications, can significantly streamline the procurement and quality assurance processes. Ensuring that the supplier adheres to international standards and maintains quality control across batches is also vital for high-reliability applications.

Materials and Manufacturing Techniques

Carrier tapes are manufactured using a variety of materials, each chosen for its specific properties. Common materials include polystyrene (PS), polyethylene terephthalate (PET), and polycarbonate (PC). These materials offer varying degrees of rigidity, transparency, and electrostatic protection. The choice of material depends on the nature of the electronic components being packaged and the environmental conditions they will be exposed to during transport and storage.

There are two primary manufacturing techniques for carrier tapes: thermoforming and injection molding. Thermoforming involves heating a plastic sheet and shaping it into the required pocket design, making it suitable for medium to high-volume production. Injection molding, while more costly, provides superior precision and strength, often used for intricate or heavy components. The supplier’s expertise in these techniques can greatly impact the final product’s reliability and performance.

Top Carrier Tape Suppliers in the Industry

Several companies have established themselves as leading providers of carrier tape solutions for the electronics industry. These suppliers have built a solid reputation by offering high-quality products, advanced customization options, and dedicated customer service. While brand names are not mentioned here, many of these suppliers are known for their extensive industry experience and adherence to global standards.

Some of the common features offered by top suppliers include:

- Wide selection of pocket depths and designs

- ESD-safe materials and packaging

- Support for custom tooling and rapid prototyping

- Global distribution networks for consistent supply

Working with a well-established carrier tape supplier can enhance production efficiency and reduce the risks associated with poorly packaged components. Manufacturers often benefit from long-term partnerships that provide technical guidance and flexible solutions tailored to evolving product designs.

Applications and Future Trends

Carrier tapes are used across various sectors within the electronics industry, including consumer electronics, automotive systems, telecommunications, and industrial controls. As components continue to shrink in size and increase in complexity, the demand for precise, high-quality carrier tapes grows correspondingly. Advanced electronics packaging requires materials and designs that can safely house increasingly sensitive devices.

Looking ahead, several trends are shaping the future of carrier tape manufacturing and supply:

- Increased use of recyclable and eco-friendly materials

- Integration of smart features such as QR codes for traceability

- Greater automation in the tape forming and inspection processes

- Enhanced data sharing between suppliers and manufacturers for better inventory planning

Suppliers who invest in innovation and align their production with sustainable practices are likely to remain competitive in this dynamic market. As the electronics industry evolves, so will the expectations for component packaging solutions.

Conclusion

Choosing the right carrier tape supplier is a strategic decision for electronics manufacturers seeking reliable and efficient packaging solutions. By prioritizing quality, customization, and compliance, suppliers can support the growing demands of high-precision component transport. As electronics continue to advance, aligning with a supplier that embraces innovation, sustainability, and global standards can provide lasting value in the supply chain. Whether for prototyping or large-scale production, a well-regarded carrier tape supplier plays a crucial role in maintaining the integrity and performance of electronic assemblies.

Leave a Reply